In the realm of industrial grinding, the choice of grinding media

can significantly impact the efficiency and quality of the process.

Among the various options available, 92% Al2O3 high-alumina ceramic

grinding balls stand out as a superior choice, especially for

non-ferrous metals.

92% Al2O3 high-alumina ceramic grinding balls are specialized

grinding media made primarily from alumina (Al2O3), with a purity

level of 92%. These balls are renowned for their high density,

hardness, and wear resistance, making them ideal for grinding

applications in industries dealing with non-ferrous metals,

ceramics, cement, and more.

- High Density and Hardness: These balls are characterized by their high density (≥ 3.65

g/cm³) and hardness (Mohs scale 9), which contribute to efficient

grinding and reduced wear.

- Low Abrasion and Corrosion Resistance: 92% Al2O3 grinding balls exhibit low abrasion rates (≤ 0.01%)

and excellent corrosion resistance, ensuring longevity and

consistent performance.

- Environmental Friendliness: Being inert and non-toxic, these balls do not contaminate the

materials they grind, preserving the purity and stability of the

final product.

High-alumina ceramic grinding balls are extensively used in the

processing of non-ferrous metals due to their superior mechanical

properties. They are a preferred choice in industries such as

metallurgy, mineral processing, and chemical manufacturing.

- Enhanced Grinding Efficiency: The high density and hardness of these balls allow for faster

grinding, saving both time and energy.

- Purity Preservation: The inert nature of alumina ensures that the grinding process

does not introduce impurities, crucial for maintaining the quality

of non-ferrous metals.

- Cost-Effective Solution: The durability and efficiency of 92% Al2O3 grinding balls

reduce operational costs by minimizing wear and extending the

lifespan of grinding equipment.

Understanding the technical specifications of 92% Al2O3

high-alumina ceramic grinding balls is essential for selecting the

right product for specific applications.

- Al2O3 Content: ≥ 92%

- Bulk Density: ≥ 3.65 g/cm³

- Water Absorption: ≤ 0.01%

- Mohs Hardness: 9

- Abrasion Loss: ≤ 0.01%

These specifications ensure that the grinding balls offer optimal

performance in various industrial applications.

When compared to other grinding media such as steel balls and glass

beads, 92% Al2O3 high-alumina ceramic grinding balls offer distinct

advantages:

- Higher Wear Resistance: Alumina balls have a significantly lower wear rate, reducing

the frequency of replacements.

- Better Efficiency: Their high density contributes to more efficient grinding,

which can lead to energy savings of up to 40–60%.

- Non-Contaminating: Unlike steel balls, alumina balls do not introduce metallic

impurities into the grinding process.

Selecting the right grinding balls depends on several factors,

including the nature of the material to be ground, the grinding

method (wet or dry), and the specific requirements of the

application.

- Material Compatibility: Ensure that the grinding balls are compatible with the

material being processed to avoid contamination.

- Grinding Method: Choose between dry and wet grinding balls based on the

process requirements.

- Size and Shape: The size and shape of the balls should match the specifications of

the grinding equipment to maximize efficiency.

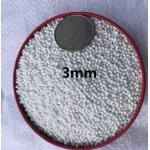

●Sizes Φ:

Size(mm) | Size(mm) | Size(mm) | Size(mm) |

0.5-1.0 | 6.0 | 20.0 | 70.0 |

1.0 | 8.0 | 25.0 | 80.0 |

2.0 | 10.0 | 30.0 | 90.0 |

3.0 | 13.0 | 40.0 | 100.0 |

4.0 | 15.0 | 50.0 | |

5.0 | 18.0 | 60.0 | |

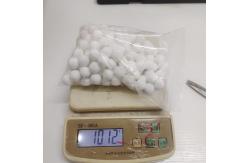

●Package:

25KG/woven bag,1000KG-1250KG for one pallet with shrink wrapped