Custom Open Die Forged Cylinder for Mechanical,Hydraulic Systems

|

|

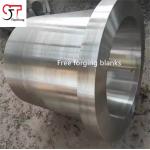

Custom Open Die Forged Cylinder for Mechanical and Hydraulic Systems Our custom open die forged cylinders are designed to meet the demanding requirements of mechanical and hydraulic systems operating under high pressure, repetitive motion, and heavy loads. Manufactured from premium carbon or alloy steel, each cylinder is forged with a controlled grain structure to improve internal strength and fatigue resistance. With flexible sizing, material selection, and optional machining services, we deliver fully tailored components for critical industrial applications.

Key Features:

Application Fields:

More products we are producing:

The steel forgings production flow: Frequently Asked Questions (FAQs)1. What is your forging capacity in terms of weight? 2. Can you perform heat treatment and machining in-house? 3. Which industries use your forged cylinders? 4. What is your standard production lead time?

5. Where is your production facility located? Request a QuotePlease send us your technical drawings and detailed specifications. |

|

Custom Open Die Forged Cylinder for Mechanical,Hydraulic Systems |

|

42CrMo4 Forged Cylinder for Hydraulic Presses and Port Equipment |

|

Heavy Duty Forged Cylinder Open Die Forging 100kg To 7000kg Custom Alloy Steel |

|

Precision Forged Steel Cylinder 42CrMo 20CrMnMo CNC Machined Rough Finished forge cnc |

|

Solid Forged Cylinder C45 42CrNiMo Pressure Vessels Marine Open Die Forging Applications |

|

Large Size Industrial Cylinder Alloy Steel Forged Heat Treated Machined To Drawing |