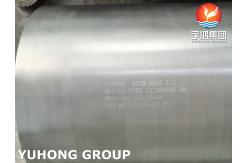

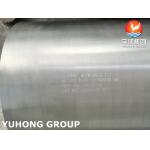

ASTM B862 Ti2 Titanium Alloy Welded Pipe For Chemical Processing

|

|

ASTM B862 Ti2 Titanium Alloy Welded Pipe For Chemical Processing

The ASTM B862 Ti2 Welded Pipe is a titanium alloy pipe manufactured according to the specifications set by the ASTM International (American Society for Testing and Materials) under standard B862. This standard governs the production of titanium and titanium-alloy welded pipes for industrial applications. Grade Ti2, also known as Grade 2 titanium, is a commercially pure titanium material known for its excellent corrosion resistance, high strength-to-weight ratio, and superior weldability.

Key Features of ASTM B862 Ti2 Welded Pipe

Applications Due to its excellent performance characteristics, ASTM B862 Ti2 welded pipes are widely used in industries such as:

Advantages of ASTM B862 Ti2 Welded Pipe

Specifications

|

||||||||||||||

| Product Tags: Chemical Processing Titanium Alloy Welded Pipe ASTM B862 Titanium Alloy Welded Pipe Ti2 Titanium Alloy Welded Pipe |

|

ASTM B862 Ti2 Titanium Welded Pipes For Heat Exchanger |

|

ASTM B862 Ti2 Titanium Alloy Welded Pipe For Chemical Processing |

|

ASME SB338 / ASTM A338 GR.7 Titanium Alloy Seamless Tubes |

|

Titanium Tube SB338 Gr1 Gr2 Gr3 Gr4 Gr5 Gr7 Gr6 Heat Exchanger Tube Industial and Medical Application |

|

ASME SB338 Gr7 UNS R52400 Titanium-Palladium Alloy Tube For Condensers |

|

ASTM B861 Grade 2 / UNS R50400 / 3.7034 Titanium And Titanium Alloy Seamless Pipe |