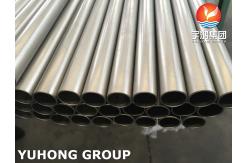

ASME SB338 Grade 7 / UNS R52400 Titanium Tube Seamless Heat Exchanger Tube

|

|

ASTM B338 / ASME SB338 Titanium Tube Grade 7 UNS / R52400 Titanium Seamless Tube

Titanium Grade 7, also known as Ti-0.15Pd (Titanium 0.15% Palladium), is a highly corrosion-resistant and weldable grade of titanium. It is part of the commercially pure titanium group and is alloyed with a small amount of palladium (approximately 0.12-0.25%) to enhance its corrosion resistance. Its corrosion resistant alpha titanium alloy with similar mechanical properties to the commercially pure grades. It has a small palladium addition to improve corrosion resistance, particularly in mineral acids and strong brines.

The Feature of ASTM B338 Grade 7 Titanium Tube

Specification

Chemical Composition of Titanium Tube

Mechanical Properties of Titanium Tube

ASTM B338 Grade 7 Titanium Tube Applications

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: astm round titanium tubing sb338 grade 7 seamless titanium tubing uns r52400 seamless titanium tubing | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

ASTM B862 Ti2 Titanium Welded Pipes For Heat Exchanger |

|

ASTM B862 Ti2 Titanium Alloy Welded Pipe For Chemical Processing |

|

ASME SB338 / ASTM A338 GR.7 Titanium Alloy Seamless Tubes |

|

Titanium Tube SB338 Gr1 Gr2 Gr3 Gr4 Gr5 Gr7 Gr6 Heat Exchanger Tube Industial and Medical Application |

|

ASME SB338 Gr7 UNS R52400 Titanium-Palladium Alloy Tube For Condensers |

|

ASTM B861 Grade 2 / UNS R50400 / 3.7034 Titanium And Titanium Alloy Seamless Pipe |