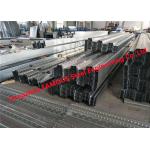

Galvanized Metal Floor Deck Formwork Floor Slab System Construction

|

Australia Standard Galvanized Metal Floor Deck Formwork Floor Slab System ConstructionQuick Detail: 1. faster erection. 2. fire-resistance. 3. high strength. 4. cost saving.

The thickness of the floor slab is 0.8mm, 1.0mm, 1.2mm, width 688mm~940mm, height 5 1 mm ~76mm. The engineering floor slab and reinforced concrete structure work together, which is a composite structure. The laying of the floor slab is connected with the steel beam, the end of the plate is welded with the steel beam, and the stud and the steel beam are penetrated and welded in the middle; the connecting plate is connected with the special clamping tongs and the pressure hole is connected; Galvanized plug plates are spot welded with floor slabs and steel beams. If the profiled cutting plate with curved area is cut by a plasma cutting machine, the slit is smooth and the surface is completely galvanized.

Specification:

Our steel deck has very effective cross stiffener technology and

the deep profile shape provides a very efficient metal deck and

composite slab, with a low usage of concrete. It has following

features:

To complete our floor decking products we advise a complete floor slab construction by adding the supply and laying of reinforced concrete. This single point solution allows a fully integrated metal deck and concrete slab with associated trade interface and program advantages.

Composite slab which is comprised of lightly reinforced concrete cast on profiled steel decking are an option whether the beams are downstand or integrated within the slab depth for a shallow floor form of construction. The slabs are normally reinforced using an upper layer of mesh and, sometimes additional bars in the troughs (usually for longer periods of fire resistance and heavy loads). Fiber reinforcement may also be used. Spans of up to 4.5 m can be achieved using trapezoidal decking. Some so-called deep decking profiles also exist (over 200 mm deep), that can span 6 m or so without propping during construction.

Product testing:

While FASEC Rebar-truss triangle welded metal decking system adapts rapid construction requirements of the main steel structure and provide fast work procedures. It can save a lot of construction time compared to traditional floor decking system. It can also improve the rigidity of the floor and save the amount of steel and concrete, so as to reduce the project budget.

The Surface embossed increase the bonding of floor deck and concrete, make the floor deck system has high-strength bearing capacity. It is totally fire-proof and can span long without middle propping.

So from cost saving and time saving view, the FASEC rebar-truss triangle welded metal decking system is better choice. However, in much of ready design, the deck is already designed and in avoiding of redesign, recalculation and re-submit/approval, we can also offer various customized steel floor deck profiles to cater for various contractors’ need, meanwhile we will offer various technical support in the aspects of load span and stress analysis etc.

Warmly welcome various clients from International market to enquiry and visit us! |

||||||||||||||

| Product Tags: Galvanized Metal Floor Deck Formwork Floor Slab System 1.2mm Metal Floor Deck |

|

Customized Composite Floor Deck Unshoring Galvanized Steel Flooring Fabrication |

|

Galvanized Metal Floor Deck Formwork Floor Slab System Construction |

|

High Performance Unpropping Metal Floor Deck Galvanized Composite Concrete Slabs |

|

Customized Composite Metal Floor Deck Staircase Construction 1.2mm |

|

Fabrication Members Steel Deck Of Cold Formed Steel Structural 980mm |

|

0.8 - 1.5mm Corrugated Metal Floor Deck Reinforced Steel Bar Truss Slab Fabrication |