220V / 380V 1000LPH Milk Pasteurization Machine 6KW With High Performance

|

|

Full-Automatic Plate HTST Pasteurizer (4 sections)

Application Scope Full automatic Plate HTST pasteurizer for Milk, soybean milk, Grape wine;flavoredd milk, or milk beverage etc. Standard configuration: A. plate heat exchanger; B. material-balance drum; C. hot water-balance drum; D. pump of hot water charging; E. pump of material transferring; F. hot water making machine; G. electricity box; H. valves and pipes of stainless steel etc.

Usage: This machine stands between the pasteurizer and the UHT, can be used for PET hot filling or roof shape filling sterilize.

Structure: Semiautomatic control: UK Spirax Sarco steam pressure reduce valve, German Burkert or Spirax Sarco temperature control system, German Labom temperature transducer, Anthone temperature recorder without paper, South hot water pump, Siemens LOGO control, the precision of temperature control is ±0.5 degree. Full automatic control: UK Spirax Sarco steam pressure reduce valve, German Burkert or Spirax Sarco temperature control system, German Labom temperature transducer, Anthone temperature recorder without paper, South hot water pump, Siemens PLC full automatic control with touch screen, the precision of temperature control is ±0.5 degree. Technical parameters: 5°C→65°C (homogenization)→120°C(15s)→25°C5°C

Control elements list:

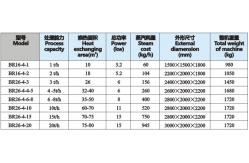

Parameter:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: dairy processing equipment milk processing plant | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

SUS304 PLC Automatic Control Soy Milk Production Machine PET Hot Filling Sterilizer |

|

Extractor Concentrator Dairy Processing Plant Automatic Industrial Stainless Steel |

|

SUS 316L Soybean Milk Dairy Processing Line Automatic Industrial |

|

Automatic Fruit Vegetable Washing Machine With Roller Drum 20TPH |

|

SUS316 Fresh Milk Processing Equipment Dairy Beverage Processing Line |

|

Turnkey Milk Processing Cheese Making Equipment Automatic CIP Clean |