291 - 300 of 1171

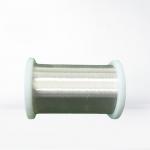

class 130 copper winding wire

Selling leads|

..., solenoids and electric motors.Additionally, the wire’s solderability allows seamless integration into complex electrical systems. In the audio ...

2025-07-21 00:08:17

|

|

...Copper Wire UEW / 2UEW 0.1 - 0.8mm Fine Enamelled Winding Wire Enameled copper wire has a wide range of applications across various industries. In ...

2025-07-21 00:08:17

|

|

... applications. With excellent structure, high temperature resistance and weldability, our litz wire is the first choice of engineers and manufactur...

2025-07-21 00:08:17

|

|

FIW4 0.12mm Enameled Copper Winding Wire High Voltage FIW Type & Diameter FIW4 0.120mm Test item Standard Value Reality value Min. Ave Max. Conductor ...

2025-07-21 00:08:17

|

0.063mm Ultra Fine Enameled Copper Wire Uncommon Size Magnet Winding Wire For Industrial Electronics

|

...COPPER WIRE UNCOMMON SIZE MAGNET WINDING WIRE FOR INDUSTRIAL ELECTRONICS Using ultra-fine wires to manufacture inductive components and provide ...

2024-12-09 22:26:03

|

|

...copper litz wire We can produce self-adhesive silk covered litz wire, hot air self-adhesive and alcohol self-adhesive. Since the ropiness optional ...

2024-12-09 23:36:38

|

|

... of 155 degrees can meet the working requirements of general electrical equipment, and its good welding performance ensures the connection quality ...

2025-07-21 00:08:17

|

|

.... This adhesive has a bonding feature, which is activated by heat or solvents. Once activated the adhesive bonds turn to turn windings into a ...

2024-12-09 22:26:11

|

|

... additional adhesive enamel overcoat. This adhesive has a bonding feature, which is activated by heat or solvents. Once activated the adhesive ...

2025-07-21 00:08:17

|

|

...Winding Insulated Copper Magnet Wire Main Features of enameled copper wire With good solderability, reduces coil production costs due to eliminatio...

2024-12-09 22:26:03

|