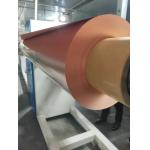

RoHS ED Electrolytic Thin Copper Foil 1 / 2 Oz Thickness High Coarse

|

Detailed Product Description

|

RoHS ED Electrolytic Thin Copper Foil 1 / 2 Oz Thickness High

Coarse ED Electrolytic Thin Copper Foil Description: ED (Electro-Deposited) electrolytic thin copper foil refers to a

type of copper foil that is produced through an electroplating

process. It is commonly used in various industries, including

electronics, printed circuit board (PCB) manufacturing, and

lithium-ion battery production. Compare between CA copper foil and ED copper foil

ED Electrolytic Thin Copper Foil Specifications:

ED Electrolytic Thin Copper Foil Features:

Typical properties of High coarse copper foil

Standard Width,1290mm,May according to the customer request tailor. Application:

FAQ: Q1: What's your guarantee? A1: All our products have 6 months guarantee after received goods,

if any quality problem can contact us. Q2: What's your delivery

time ? A2: The common delivery time is 5-35 working days. The

specific delivery time depends on the items and the quantity of

your order. Q3: What's your minimum order quantity? A3: The MOQ is 150 kg. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: thin copper sheet copper foil tape | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Related Products

|

RoHS ED Electrolytic Thin Copper Foil 1 / 2 Oz Thickness High Coarse |

|

10 Mic LB Single Shiny ED Battery Thin Copper Foil Parallel Hybrid Electric Vehicle PHEV |

|

6Inch 152mm Electrolytic Rolled Thin Copper Foil Sheet Reach |

|

5 Micron Copper Foil, Thin Copper Foil supplier for Lithium Ion Battery |

|

HD Thin Copper Sheet For Polyimide Board Min 160 MPa Tensile Strength |

|

3 / 4 Oz Thin Copper Foil For Epoxy Board High Ductility None Pinholes |

Email to this supplier