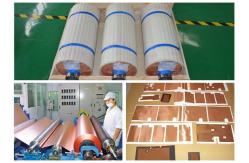

High Ductility Copper Foil For Pcb , ISO Width 1380mm Copper Sheet Plate

|

|

35um High ductility electrolytic copper foil with width 1380mm

3. Standard Width,1380(±1)mm,May according to the customer request

tailor. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

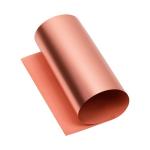

| Product Tags: pure copper foil copper sheet plate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Electric Vehicles PCB Copper Foil Li-Ion Battery Copper Foil |

|

25um LP Ed Copper For FPC , High Temperature Resistance Copper Foil Roll |

|

Clad Laminates / CCL Electrolytic Copper Foil Rolls 35 Micron Thickness |

|

Double Side Shiny Copper Foil Thickness 4.5um 6um For Electric Vehicles Li-Ion Battery |

|

4.5um 6um Double Side Rough Copper Foil For Lithium Ion Battery |

|

Matte Side Treatment Very Low Profile Copper Foil 10um 12um 18um 25um 35um |