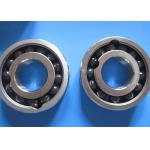

Ceramic Plain Bearings Sic Ceramic Balls , Higher rigidity Lower Rupture Toughness

|

Detailed Product Description

|

Sic Ceramic Ball The density of Sic Ceramic Ball is 3.2g/cm3 and it’s the same as Si3N4 ball, at 1400℃, the intension and rigidity almost couldn’t be changed. Sic Ceramic Ball has the self-lubrication that can solve the pollution of lubricate medium. Comparing with Si3N4, Sic Ceramic Ball has higher rigidity, lower anti-press strength and lower rupture toughness.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: full ceramic bearings ceramic ball bearings | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Related Products

|

Corrosion Resistance Ceramic Plain Bearings ZrO2 Material Ceramic Cage |

|

High Precision And Mini size Full Ceramic Bearings ZrO2 Or Si3N4 |

|

Full Complement Balls Ceramic Plain Bearings Si3N4 For High Speed Circumgyration |

|

Full Ceramic Ball Bearings ZrO2 Full Ceramic Bearings 1300 HRC |

|

Hybrid Construction Ceramic Ball Bearings , GCr15, AISI440C, 316, 304 For Inner & Outer Ring |

|

Ceramic Plain Bearings Sic Ceramic Balls , Higher rigidity Lower Rupture Toughness |

Email to this supplier