JF Sheet Metal Technology Co.,Ltd

|

JF Sheet Metal Technology Co.,Ltd,founded in 2007, is a leading manufacturer of metal fabricator for stainless steel and aluminum products, RK Bakeware Co.,Ltd, a sister company of JF Sheet Metal Technology Co.,Ltd, is a leading manufacturer for making industrial and commercial bakeware products.

The company has a large number of advanced equipments, and innovative spirit of the design team,the existing professional design team, skilled technical processing personnel, all kinds ofprocessing and testing equipment, CNC machiningcenter, 100 super laser cutting machine, 100 super CNC bending machine, MURATA CNC punch andother mechanical processing equipment, but alsoprovide all kinds of electric welding and injectionservice, to provide customers with high efficiency and high quality automation equipment to lay a solid foundation. We look forward to working with you to cooperate, to create brilliant!

JF Sheet Metal is located in the shore of the beautiful Taihu Lakein Wuxi City , covers an area of about 3000 m2.Business scope: automation equipment, precision machining, plastic parts, processing and assembly, and the production of various commodities, technology import and export business. At present in the textile machinery industry has been a very good reputation,product in the domestic market has occupied the certain share, and exported to the United States, Russia, Japan,Brazil Singapore,Turkey and other countries.

Business philosophy: the company was founded in the beginning of our spirit of "quality, service, value" concept, to market demand as the guide, to provide customers with the best products and the best service for the purpose. From raw material purchase to production and processing technology and quality management, strict control, fully achieved national certification standards, and passed the ISO9001:2008 certification.From product project, research and development, quality control, production management tothe product packaging and transportation and otherlinks will be with customers to maintain a full range of communication, to ensure that the customer's reasonable suggestions can be transformed into the company's instructions, in all aspects of the business to be effective implementation. EPR production management, to achieve flexible production, in the premise of ensuring the quality, the maximum degree of meet customer needs.

Cultural idea: "pragmatic, pioneering and innovative" is our cultural idea. Only by using the pragmatic will we learn to adapt to the development of our society and our company, we will be able to work well; only a continuous development can inspire us to go beyond ourselves. Only by constantinnovation can we have a more dynamic and competitive ability.

Talent concept: in the course of business, the company always adhere to the "people-oriented" concept. We firmly believe that talent is the main body of all business activities, and the elite talent is in the company's specific cultural atmosphere in the cultivation and training. At present, the company has more than 50 employees, including more than 5 designers, technical service personnell. Some of the staff through the company's (internal / external) training and their own efforts, from the first position to the management position. Companies to cultivate talent, and talent will in turn promote and promote the development of the company. We respect talent, care for talent, more concerned about the growth and development of talents. We are committed to the growth and development of talents to provide a first-class working environment and cultural atmosphere, here is not only a platform for the development of personnel training, but also a platform for the development and expansion of the company. Finally, to promote the development of individual talent and the company to achieve maximum win-win!

|

- Basic Information

-

Company Name: JF Sheet Metal Technology Co.,Ltd Business Type: Manufacturer,Exporter,Trading Company Brands: JF Employee Number: 50~200 Factory Location: 212, Xingtang Road, Xishan district, Wuxi City, Jiangsu, China, 214000 - Trade & Market

-

Company slogan: A Leading Industrial and Commercial Bakeware Manufacturer In China

OEM Overview: JF sheet metal technology co.,ltd set up in Aug 2007,located in wuxi jiangsu china .We are focusing on sheet metal fabrication only ,providing quality products and service with support high engineering strength, automatic machinery ,well-trained operators and integrated management .

Providing on-stop solution for sheet metal parts and assemblies based on customers drawing and designs .

We have almost 10 years

Production Line: About Process

This is baking pan product process.

This machine automates the production line, it is efficient and fast, and the product quality is guaranteed.

This is the mould manufacturing equipment.

This is a 60T oil press.

This is the AMADA CNC punch.

No.1 CNC laser cutting

We own two laser cutting machines imported from Bystronic. The maximum thickness of sheet metal is 25.0mm, and the tolerance of processing precision is ±0.1 mm.

NO.2CNC lathe machine

NO.3 CNC bending machine

We have two CNC bending machine from Bystronic, five ACL CNC electrohydraulic synchronous CNC bending machines and one common hydraulic plate bending machine.

It has the maximum bending width of 4,100mm, and the maximum post-positioning size of 1200mm, maximum tonnage of 320t, and processing precision tolerance of ±0.004 mm.

We can make full use of performance and advantages of bending machine to make satisfied and fine products for customers.

NO.4 Welding

We have 6 CO2 shielded welding machines and 6 argon arc welding machines.

We can rationally divide labors for splicing, spot welding, full-length welding, polishing, and inspection, in this way, we can find out and correct problems in time, and ensure quality of welding products.

NO.5 Deburring machine

NO.6 Swiss HRC precision leveling machine

No.7 CNC Turret machine

We own two turret stamping CNC presses imported from MURATA. The maximum width of processed metal sheet is 1525mm, and the tolerance of processing precision is ±0.1 mm.

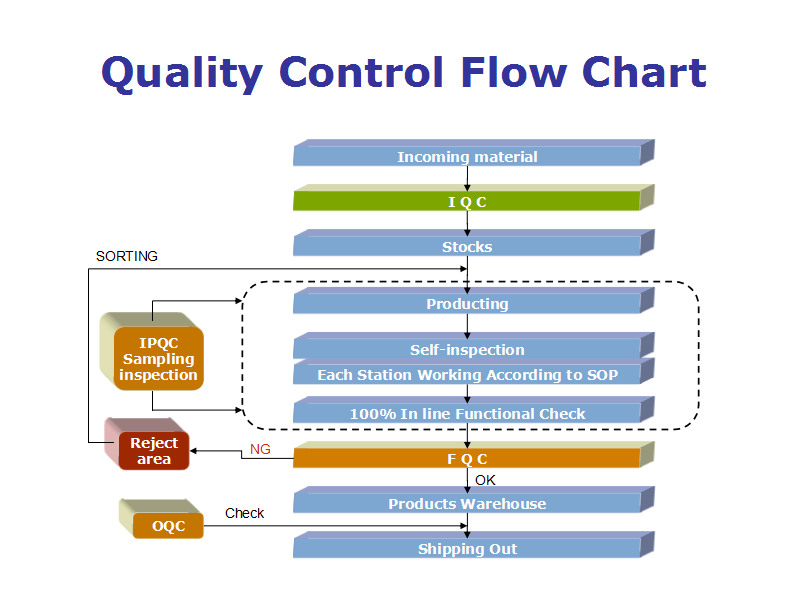

About quality management: Quality control flow

Before we buy raw materials,we will evaluate the supplier ability and reliance and vendor surveillance and past time credit. Then first we have IQC(incoming raw materials control),when we buy raw materials,we will test raw materials at first by spectrometer in the lab.Second we will check raw materials size and thickness tolerance ,must within the allowance of drawing,third we will check the surface of raw materials,if have some scar or scratch.

Second step is IPQC(In-putting quality control),we have first article inspection before mass production and roving inspection,and each tollgate we need the worker check and sign for it to guarantee the article is correct to go to next step.

Third step is OQC(Outgoing quality control),during this step,we will spot check several item to check if the quality is stable and within control.

For big size part(such as side plate and pontoon,we check one by one both surface and size and welding(For welding parts,we will check according to drawing the length of welding line and height and width of welding line),for small punching parts,we will spot check,and by the while ,we will check the quantity also to guarantee no shortage for hmt.And Some surface have bur,we will need process by deburring .

The Forth step is QE (Quality engineer),QE will do analysis and audit to the quality control system if it is effective and feasible.

This flow chart show us the flow how the article produce out from raw s to final product.

Incoming material-IQC(In coming quality control)-stocks(stock at warehouse waiting for production plan arrangement)-producting-self inspection,each station working according to SOP(standard operation practice)-100%in line functional checking-FQC(final quality control)-products warehouse-shipping out

Last step is loading quality control.

We will assess the safety of loading and packing way before loading.Such as how to pack the goods,what kind package to use and the how is the packing load-bearing,and we will design different size wooden crate for different products ,such as shoe plate.And for easy getting hurt products,we will use such as a sponge attached to the interior of the container to ensure that products are not getting hurt.Such as pontoon.And we will instruct the worker to handle the products appropriately ,and workers when in operation, need to be careful and orderly loading.

Our Team: The company has a team of entrepreneurs composed of highly educated and high-quality talents.As a team engaged in e-commerce industry in China, the company has witnessed the rapid development of e-commerce since its 10th anniversary, accumulated rich experience in food e-commerce operation, and formed a scientific management system.Team members are young and energetic, innovative and brave to meet challenges.Have a good sense of social responsibility, is willing to improve the status quo of China's bakery industry, contribution.

- Factory Information

-

Market name: North America,South America,Southeast Asia,Middle East Contact Person: Mr.Jack Wang Contact Phone: 86-0510-15052223631