Zhejiang Ukpack Packaging Co., Ltd.

|

COMPANY INTRODUCTION

ZHEJIANG UKPACK PACKAGING CO,.LTD is a professional manufacturer of platic packaging.We have two factories, located in Zhejiang, Ningbo, where a factory produces bottles, and another factory produces pumps. The factory coves an aea of 3800 square meters.Workshop lands 5000 square meters. Our company implement dut-fre and closed production. Carry out 6S management model. Excellent workers produce high quality products, and top-class teams, from a outstanding enterprise. Our company is a blend of the world's most advanced technology and management methods, we create unexpected value and service for the customer with vigor and vitality. Our company established in November 2014, specilize in all kinds of high-gade cosmetics chemical and medical plastic packaging, existing nearly 30 staffs. Has a group of R&D, design, management and advanced produdion equipment and domestic and foreign well-known brands of raw materials suppliers. From product development, mould making to commodity production, assemble. we form a complete set of prodution. With mould procesing equipment over 30 sets, 21 injection machine, 10 pieces of double die head and double station blowing machines, and various kinds of secondary processing equipment.An annual output are 50 million sets for plastic products. Form a complete set for the domestic and foreign famous cosmetics brand product.

CERTIFICATE We have ISO9001 quality management system certification and a number of patent inventions

FAQ: 1. Are you factory or trading company ?

We are factory located in Ningbo Yuyao City,Zhejiang Province

2. How to get a quotation and start business relationship with your company?

Please send us email and our sales will contact you within 2 hours,or Direct call us +86 0575 82937072(Cell-phone numbe:+86 13867191426)

3. How to receive a price quotaion in the shortest time?

When you send us an enquiry, please kindly make sure all the details, such as order quantity,colour ,package etc

4. What types of payment terms do you accept?

Currently, the payment terms we accept are T/T (30% before production, 70% down payment before delivery goods)

5. Before shipment, how to make sure the products quality?

If you don't come to our factory and also don't have the third party for inspection, we will be as your inspection worker. We will supply you some picture&check report

6. What is your MOQ?

As an usual,our MOQ is 10,000pcs/order.

7. Can you get free samples from you ?

Of course,you can .But freight you will charge.

8. Can we combine some item size in one container at first order ?

Of course ,you can .This is our most professional service project,but every item quantity need reach our MOQ

9. How do you control quality?

We will make samples before mass production,after samples approved by customer,will start mass production.Doing 100% inspection during the production and dospot inspection before packaging.taking picture after packaging

10. If any quality appear,how can you help us to solve ?

If any break or defect product found ,you must take picture for us from the original carton .Our sales will give you final solve method with 2 hours.we will make up for your loss.

|

- Basic Information

-

Company Name: Zhejiang Ukpack Packaging Co., Ltd. Business Type: Manufacturer Brands: UKPACK Employee Number: 100~150 Factory Location: Shangyu Yuexiu Road E-commerce industrial Park, Room 337,Zhejiang 312000 PR China. - Trade & Market

-

Company slogan: ZHEJIANG UKPACK PACKAGING CO,.LTD

--One stop cosmetic packaging solutions provider

OEM Overview: Process Service

- We have our own service people to help you solve problem 7*24 hours.

- We will have good service before sales during sales,after sales,if has quality problem,we will provide scheme in time of course,if need us to solve to your place we will arrange enigneer to solve at the first time.

- All customers’ request will be reply on the day.

- About new product, we will help customer develop, design,making,contain whole process.

Production Line: PRODUCTION STRENGTH

The company has advanced production equipment and high precision, including mold processing equipment more than 30 Taiwan, injection molding machine 21 units, double head double station blow molding machine more than 10 units and various secondary processing equipment, witH the production from product development, mold to the injection molding, blow molding, assembly,printing, and improve the production chain, all kinds of technical engineers and dedicated front-line workers team, to ensure the plastic UKPACK product quality has been in a leading position in the industry.

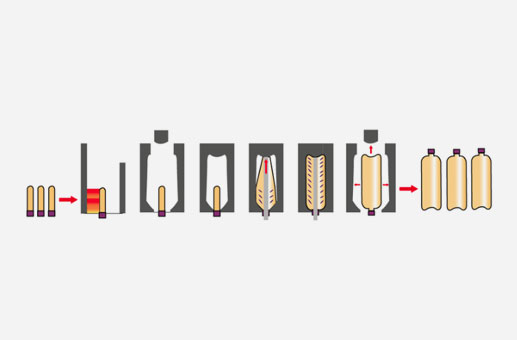

INJECTION

Plastic pellets are fed into the hopper. The Screw conveys and melts the pellets. The melted plastic is forced into the mold and the part is formed and cooled. The mold opens and the part is ejected.

INJECTION BLOW

The parison is clamped into a mold and air is blown into it. The air pressure then pushes the plastic out to match the mold. Once the plastic has cooled and hardened the mold opens up and the part is ejected.

INJECTION STRETCH BLOW

The Parison is heated or cooled specific locations to prepare for stretch blowing. The parison is clamped into a mold and air is blown into it. The air pressure then pushes the plastic out to match the mold. Once the plastic has cooled and hardened the mold opens up and the part is ejected.

EXTRUSION BLOW

Parison is heated and captured by closing it into a cooled metal mold. The air pressure then pushes the plastic out to match the mold. A trimmer cuts off the excess plastic on the top and bottom of the Bottle and is ejected from machine.

Extrusion blow

Injection molding

Injection blow

Assembly

Printing

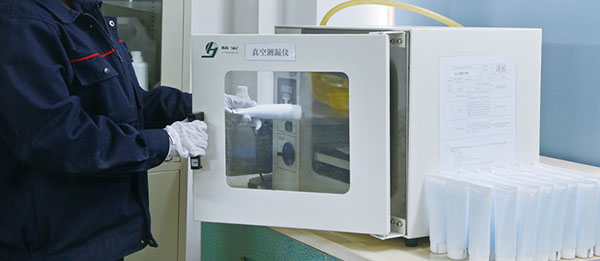

About quality management: Cosmetic Packaging Quality Management

Cosmetic packaging quality management is a critical aspect of ensuring the integrity, safety, and appeal of cosmetic products. It involves a set of processes, standards, and practices aimed at maintaining consistent quality throughout the packaging production and supply chain. Here are some key considerations for cosmetic packaging quality management:

Supplier Selection: Choosing reliable and reputable packaging suppliers is crucial. Evaluate suppliers based on their track record, quality certifications (such as ISO 9001), compliance with regulatory requirements, and their ability to meet specific packaging quality standards.

Quality Standards and Specifications: Define clear quality standards and specifications for the packaging materials, including dimensions, tolerances, materials, printing quality, labeling requirements, and any specific regulatory compliance guidelines. These standards should be communicated to suppliers and regularly reviewed and updated as needed.

Incoming Inspection: Implement a rigorous incoming inspection process to ensure that the packaging materials received from suppliers meet the defined quality standards. This may involve visual inspections, dimensional checks, material testing, and verification of regulatory compliance.

Process Control: Establish process controls to ensure consistency and quality during the packaging manufacturing process. This includes monitoring key parameters, such as temperature, humidity, and production speed, to maintain the desired quality levels. Regular equipment maintenance and calibration are also essential to prevent quality issues.

Quality Assurance Testing: Conduct appropriate quality assurance testing on the finished packaging products. This may include tests for durability, functionality, compatibility with the product, and other specific requirements. Testing methods can vary depending on the packaging type, such as drop tests, leakage tests, or barcode readability tests.

Regulatory Compliance: Ensure that the cosmetic packaging materials comply with applicable regulations and standards, such as those set by the FDA (Food and Drug Administration) or equivalent regulatory bodies in different regions. Stay updated with the latest regulations related to packaging materials, labeling, and safety requirements.

Traceability and Documentation: Establish robust traceability systems to track and document the packaging materials used for each batch of cosmetic products. This enables easy identification and recall of specific batches in case of quality issues or regulatory non-compliance.

Continuous Improvement: Implement a system for monitoring, analyzing, and addressing quality-related issues. Regularly review and evaluate the effectiveness of quality management processes, and proactively seek feedback from customers and end-users to identify areas for improvement.

Good Manufacturing Practices (GMP): Adhere to Good Manufacturing Practices specific to cosmetic packaging. This includes maintaining a clean and hygienic production environment, proper storage of packaging materials, and ensuring the integrity of packaging components.

Quality Audits: Conduct internal audits and periodic quality assessments to ensure compliance with quality standards and identify areas for improvement. Additionally, consider third-party audits or certifications to provide an independent evaluation of packaging quality.

UKPACK By implementing effective cosmetic packaging quality management practices, can enhance customer satisfaction, minimize quality-related risks, meet regulatory requirements, and strengthen their brand reputation in the market.

Services: R&D DESIGN

Success in today's beauty industry requires packaging that both captivates and compels. It must be intuitive and convenient, yet refreshing and new. And because our industry and the desires of consumers are constantly evolving, perfection today guarantees nothing tomorrow.

That's why we do not wait to develop packaging that works harder. Longer. Better. And more cost-effectively. Our job is to ensure that no matter what your needs my be tomorrow, we're already hard at work on them today.

Our award-winning team is esteemed throughout the industry for its abililty to antcipate issues before they arise, pioneer groundbreaking products and solutions, and not only predict market trends - but define them.

UKPACK always pay attention to technology research and product innovation, througH the new raw materials new technologies, new products continue to researcH and development, keep the company in the packaging industry's technology leading edge.

05ZIUFNA7JU.png)

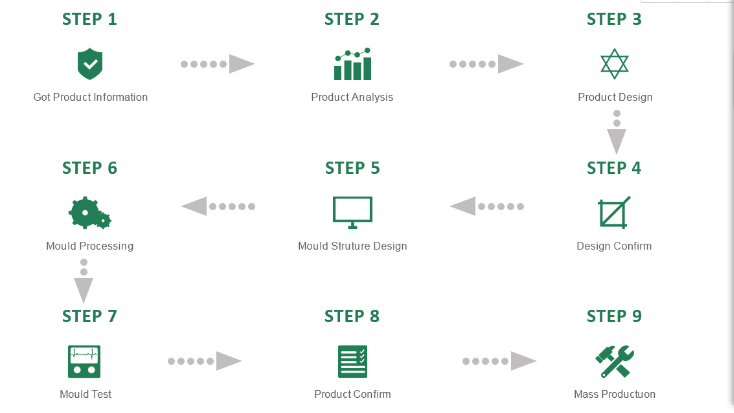

Product Design Steps

When we get customer's product information ,we will call up our related department to analysis the product within 1 day and then our professional designer will arrange for product design on the day.2D and 3D product drawing will be finished within 2 days.

Our Team: Our quality management team

Product R & D team

Mold manufacturing team

Printing team

- Factory Information

-

Market name: North America,South America,Western Europe,Eastern Europe,Eastern Asia Contact Person: Mr.Lucas Contact Phone: 86-575-82937072

0_PA[9G$9YKY$L5QB36{V.png)