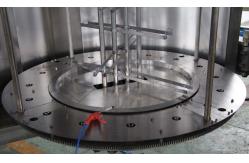

Plastic Vacuum Metallizing System, Plastic parts aluminum metallization machine

|

Detailed Product Description

The PVD metallizing process gives the objects a high shiny, reflective, metallic look which can be in different colors.

Royal Technology has designed, built and installed over 100 sets of thermal evaporation coating systems worldwide, encompassing a variety of applications and industries, such as:

Only to name a few, in many other areas PVD vacuum metallizing processes are continue to be used and developed in the coating industry. Royal Technology- High Vacuum Metallizing Equipment —–Large Batch, Fast Cycle, High Yield PVD Vacuum Metallization Process

The whole process is quick and highly improves the quality and beauty of materials.

Benefits

Royal Technology provides small, medium and big size models for your option, you can always find the proper one with our technician’s assistance.

Insite |

| Product Tags: small pvd coating machine vacuum coating plant |

Related Products

|

CsI High Vacuum Deposition System -RT-CsI950 |

|

High Vacuum Metallizing System, Thermal Evaporation Coating Unit For Fingerprint Mark Imaging |

|

Au Gold Pvd Plating Machine Thermal Evaporation For Fingermark Imaging |

|

Fingerprint display vacuum metallizer |

|

Forensic Police Equipment, High Vacuum Metallizing System, Zinc/Gold/Silver/Aluminum PVD Metallizing Equipment |

|

Gold PVD Vacuum Metal Deposition on Forensic Application / Au Thermal Evaporation on Fingerprint Mark Imaging |

Email to this supplier