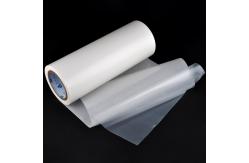

Polyurethane Film Double Sided Hot Melt Adhesive For Fabric

Lamination

Product: DS8501

Description:

This product is a thermoplastic material, for a variety of

materials can be applied to the hot melt adhesive, It can

repeatedly heated plastic bonding. This kind of hot melt adhesive

has good adhesion to textile, polyester, cotton, blended fabric,

TPU, PVC, PC / ABS, and has good resilience, elasticity, heat

resistance, cold resistance and water resistance .

Applications:

DS8501 development direction and application is for clothing,

shoes, textile accessories, handbags, luggage, ipad protective

cover, mobile phone protective cover, sports equipment and other

materials bonding.

Composition:

Polyurethane

Physical Characteristics: | Color | transparent | Release liner | Glassine release paper | | Density | 1.18±0.02g/cm3 | Thickness | 0.0125mm-1mm | | Opening Time | 10min | Width | 5mm-1500mm | | Hardness | 82±2 Shore A | Conventional thickness | 0.08mm,0.1mm,0.15mm | | Melt Flow Index | 5±1g/10min;

Condition:ASTMD1238-04 | Conventional Width | 1380mm | Rheology Temperature | 112°C | Length | 100 yards | Operating temperature

| 130°C -160°C | Finished products specification | 1380mm*100yards/roll |

Recommended Bonding Conditions: | Flat Press | Second Flat Press | | Machine Setting: 120℃-140℃ | Machine Setting: 130℃-160℃ | | Dwell Time: 5-15 seconds | Dwell Time: 8-25seconds | | Pressure: 0.3-0.6mpa | Pressure: 0.3-0.6mpa |

1, Bonding temperature and pressure as well as the time involved in

the strength of the film to material. Bonding temperature must be

close to the machine set the temperature, the pressure must be

uniform, mold and pressure roller must be flat.

2, In different machinery and materials, the bonding conditions

used will be different. The conditions marked here are only basic.

The optimum bonding conditions should be made by creating suitable

construction conditions for the particular application damage,

direct or consequential, arising out of the use, misuse or

inability to use the product.

Certifications Our company has passed ISO9001:2015 quality management system

certification, and all products in our company are up to

RoHS,REACH, Oeko-tex, California Proposition 65, Halogen Test

Report, PFOA, PFOS, PAHS, HBCDD and other environmental standards.

Our Service:

1, Your inquiry will be replied within 24 hours and online service

is available all the time.

2, Well-trained & professional sales persons are here ready to

answer all your questions and handle the problems.

3, Prompt delivery time: within 15 days after agreement

4, Flexible payment terms: T/T, L/C, O/A, Western Union, Paypal,

Escrow, etc.

5, Your business relationship with us will be confidential to any

third party.

6, Good after-sale service offered, please get back if you got

question.

FAQ 1, Q: How will you pack the product?

A: We pack with paper cartons, usually 4 or 6 rolls per carton for

hand stretch film; 1 roll for machine stretch film; 56 or 84 rolls

for mini stretch film and 27 rolls per pallet for jumbo stretch

film. 2, Q: How many rolls can be full fitted into one container, such as

20FT, 40FT?

A: The details are in the above forms. If your specification is

different, you need to tell us the size of the carton, and then we

will calculate for you accordingly.

3, Q: How about the adhesive of the stretch film?

A: It is self adhesive stretch film. We can produce one side and

two sides adhesive but usually one side adhesive. Besides, the

stickiness can be controlled as customized.

4, Q: How many layers of the stretch film can your equipment make?

A: Our equipment can produce 1/2/3 layers stretch film.

5, Q: Do you accept OEM?

A: Yes, we do.

6,Q: What’s your payment term?

A: We accept T/T, L/C, O/A, Western Union, Paypal, Escrow, or

customized if it is acceptable.

Contact Me

|