Machine main parameter

| PCB length width | Max:500*350mm min:50*50mm |

| mounting speed | 45000CPH Optimal speed |

| No. of head | 10 PCS |

| Feedering way | electric feeder with double motor |

| No. of Camera | Cylinder clamping,track width adjustable |

| Power&power consuption | 220V 50HZ 1.5kw |

| components | led chips,resistor,capacitor,IC,shaped components,etc |

| X,Y axis drive way | high-end magnetic linear motor |

Features of YT10S SMT pick and place machine

Head Flight Vision recognition Camera

Components with size less than 10mm high-speed and high-precision

identification.

●Mark recognition:High-precision Mark recognition system,adopt

3 color illumination recognition. apply to any shape Mark and

LENS(Blu-ray scan),wider range of applications.

●Fixed flight vision camera:High-speed flight vision camera,quickly

captures multiple head images at once, perform visual calibration

of image position,alignment correction,adjustable light source

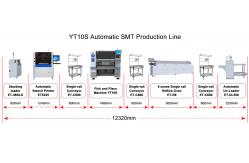

Production Process

Step 1 | Loader Machine | Sending the FPCB roll to printer machine |

Step 2 | Automatic Stencil Printer | Printing the solder paste on the flexible PCB |

Step 3 | Buffer Stage | Buffer and transport the flexible PCB to pick and place machine |

Step 4 | Pick and Place Machine | Mounting LED chips and components on flexible PCB |

Step 5 | Transportation Belt Line | Transport the flexible PCB to reflow oven |

Step 6 | Reflow Oven | Heating the solder paste with FPCB to welding the components on

FPCB |

Step 7 | Unloader Machine | Rewinding the finished Flexible strip |

Certificate of honor

ETON, a leader in advanced technology and innovation, spearheads rapid

market transformation through its cutting-edge solutions.

The company has secured numerous intellectual property rights and

earned prestigious accolades, including:

- Shenzhen High-Tech Enterprise Certification

- National High-Tech Enterprise Certification (China)

- Shenzhen Premier Brand

- 2015 LED Technology Innovation Award

- Fourth China LED Innovation First Prize (2015)

These recognitions underscore ETON’s commitment to driving

technological excellence and reinforcing its position as an

industry pioneer.

After sales service

After-service

■ Pre-Consultation: provides professional SMT solutions for the

full line.

■ Factory Warranty: One-year warranty factory service.

■ Installation: On-site installation and commissioning, to ensure

smooth production.

■ Technical Training: provides professional training from Level 1

to Level 3.

■ Technical Support: provides 7 * 24 technical support.

■ Software Upgrade: offers lifetime free software upgrades for all

products Provide latest information about technology and equipment.