10 Nozzles Integrated Mounting Head SMT Placement Machine with Independent Software

|

|

Integrated mounting head 10 nozzles intelligent SMT placement machine

Machine main features 1.X,Y,and Z axis all adopt self-developed high-end magnetic linear motor 2.Flexible PCB handling capabilities, multi-station,multi-material mounting 3.Y axis adopts double drive gantry structure 4.Support automatic replacement nozzle function(option) 5.Apply to 0201~35*35mm tape reel package and IC tray feeder ● Single gantry, 10 splines. ● Maximum PCB board: 500*450mm, minimum 50*50mm. ● Optional IC cabinet,ANC, flexible production ● Flexible wiring is achievable through modular placement Heads and various production modes. Machine main parameter

Certificates As an experienced manufacturer in SMT machine, we obtained a number of intellectual property technologies, including 9 invention patents, 112 practical patents, 12 software copyrights, with our won R&D department for production and inspection. And also earned the oversea certificates as CE, CCC, SIRA,etc. Market Our products had exported to more than 30 countries and regions, including South Korea, India, Vietnam, Tunisia, Egypt,Turkey, Russia, Brazil etc. And here are some of our big customers: SURYA, POLYCAB, FIEM, RK, GK, TECHNO LED, CALCOM, ACK , KENDAL, RangDong, UNISTAR, and so on. Packages Step 1: Wrap with stretch film to prevent the equipment from. Step 2: Vacuum paper packaging and moisture-proof bag, so that the machine can be kept dry during transportation to prevent moisture. Step 3: Use straps and triangular wood to fix the machine to prevent damage to the machine during transportation. Step 4: Each exported machine will be equipped with sturdy export wooden boxes, to ensure that the delivered product is good.

FAQ Q.What kind of machine you have? AWe are the high speed SMT pick and place machine manufacturer, and also we build our brand to more efficient and convenient machine for our customers. We have multifunctional type, honor series, value series with high precision and high productivity.

Q. What is your actual speed of your products? A. For the actual speed of the machine which is constrained by many factors, that related to the number of the components, the time to send PCB board and receive the board that will have influence on the speed when in production, and is decide for the actual products and needs.

Contact me: Whatsapp/Wechat: +8613632769526 Email: Noah@eton-mounter.com

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Independent Software SMT Placement Machine Integrated Mounting Head SMT Placement Machine 10 Nozzles SMT Placement Machine | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

104 Feeders smd mounting machine, 98000CPH SMT Mounting Machine YT20S |

|

Higher Efficiency Surface Light Emitting Diode SMT Mounter for the German Market |

|

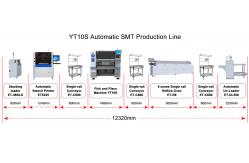

YT10S SMT Production Line With Electric Feeder With Double Motor |

|

Led Tube PCB Processing machine HT-F7s high speed SMT Mounting Machine |

|

0201 led light/driver making Machine ETON 10 heads pick and place machine |

|

1850kg Total Weight Pick and Place Machine for 0.5-5mm PCB Thickness at a Competitive |