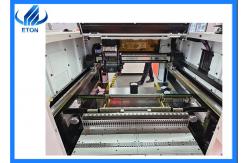

High Precision LED Electrical Board Pick and Place Machine 220V ≤16mm Mounting Height

|

|

220V low energy consumption LED electrical board pick and place machine

Machine main features 1.X,Y,and Z axis all adopt self-developed high-end magnetic linear motor 2.Flexible PCB handling capabilities, multi-station,multi-material mounting 3.Y axis adopts double drive gantry structure 4.Support automatic replacement nozzle function(option) 5.Apply to 0201~35*35mm tape reel package and IC tray feeder ● Brand new self-developed high-precision placement head. ● Combining high-accuracy mark recognition camera with a fixed-flight vision camera to ensure placement accuracy. ● The placement head adopt independent vacuum detection,improve placement performance. ● Off-line programming,saves time during changeover cycles. ● The software includes Al Deep Learning and Automatic Optimization functions. ● Supports providing an MES system interface. ● Equipped with coordinate import function.

Machine application SMT Line solution The SMT production line has two schemes: semi-automatic and fully automatic line. If you are just starting to do it, I suggest you do a semi-automatic production line, which can effectively save your cost. The equipment required for the semi-automatic production line includes:

Our Exhibitions Participate in various exhibitions at home and abroad every year (except during the epidemic period) Domestic exhibitions: Guangzhou Guangya Exhibition, Shanghai Munich Exhibition, Chongqing LED Light Exhibition, etc. Foreign exhibitions: India Mumbai Exhibition, India Delhi Exhibition, Egypt Exhibition, Turkey Exhibition, Pakistan Exhibition, Thailand Exhibition, etc. Shipping and Delivery Shipping Way: ※ By air, for sample and small package ※ By sea, for large package and quantity; ※ Other ways as customer requested. Delivery Time: ※ Within 30 Days. FAQ

Q. Can you accept CIF as the quoted price? A. We only accept EXW as the quoted price for it is convenient and lower cost for both sides.

Q.Can I pay by L/C. A.The procedure of L/C payment is complicated, which will waste a lot of time on payment. For more, you need to wait longer to get the machine, which will delay your production plan and delay the opportunity.

Q. How many products can your machine make per day? A. The capacity of our machine is according to the real products, and the number of components on your PCB board that is important factor to figure out the actual speed of our machine with your products.

Contact me: Whatsapp/Wechat: +8613632769526 Email: Noah@eton-mounter.com

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Electrical Board Pick and Place Machine LED Board Pick and Place Machine Pick and Place Machine 220V | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

104 Feeders smd mounting machine, 98000CPH SMT Mounting Machine YT20S |

|

Higher Efficiency Surface Light Emitting Diode SMT Mounter for the German Market |

|

YT10S SMT Production Line With Electric Feeder With Double Motor |

|

Led Tube PCB Processing machine HT-F7s high speed SMT Mounting Machine |

|

0201 led light/driver making Machine ETON 10 heads pick and place machine |

|

1850kg Total Weight Pick and Place Machine for 0.5-5mm PCB Thickness at a Competitive |