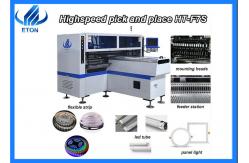

180000cph SMT Pick And Place Machine For LED Light / 0402 Components

|

|

SMT pick and place machine in led light for SMT mounting

Features we have another economic high speed mounting machine F7S. It is a dual-arm professional high speed mounter,2-4 types of materials capacity reach 180000 CPH. this machine has two mounting module,18 nozzles for each mounting part,part A or part B can be mounted separately or synchronously. It apply to the 0.6m 0.9m,1.2m rigid PCB and 0.5m,1m LED roll to roll soft strip light.producing with 2-7types of materials with high capacity,available for PCB board with any proportion of LED components.compared with F9, the NO.of head of f7s is less than F9,that is why f7s is lower than F9 in capacity.

Technical parameter Dimension:2700*2300*1550mm Total Weight:1700kg PCB Length Width:Max:1200*330mm Min:100*100mm PCB Thickness:0.5-5mm No.of Feeder:68pcs No.of Head:34pcs PCB Clamping:Adjustable pressure pneumatic Mounting Mode:Group picking and separate placingseparate picking and separate placing Software:R&D independently Mounting Precision:±0.02mm Mounting Height:<=5mm (Automatic Changing) Mounting Speed:150000-180000 CPH Components:LED,capacitors,resistors,rectifier etc. Transmission Direction:Single direction (option)

SMT machine scrubbing Use is to mount a good PCB board on the human body there is a book on the transport according to the residues such as help to remove the bubble. The position can not be fixed, can be on-line, can not be on-line:-structure: the cleaning machine is a fully automatic, the process is controlled by PLC, 6 sections made of stainless steel material, ultrasonic cleaning chamber, medium pressure spray cleaning chamber, medium pressure, spray rinsing, the cleaning device consists of a chamber, a water absorption chamber, a wind knife cutting water chamber, a blanking section and a Teflon mesh belt plane conveying system. How it works: the PCBA washer uses an ultrasonic generator to generate a high-frequency current, which is converted by the piezoelectric effect of the Ultrasonic transducer into mechanical waves of the same frequency, there are tens of thousands of tiny bubbles in the cleaning fluid, which form and grow in the negative pressure region, and break up quickly in the positive pressure region. The process of the formation, growth and rapid rupture of these tiny bubbles is called“Cavitation effect”. When cavitation occurs, the instantaneous quotient pressure of more than 1,000 atmospheres is formed from the instant of the formation, growth and rapid rupture of tiny bubbles, the constant instantaneous high pressure of the wire is like a series of small bombs hitting the surface of the cleaning object, causing the surface of the object, the gap, and the adhesion in the blind hole to quickly peel off the dirt, this cavitation effect is the basic principle of ultrasonic cleaning. With the appropriate cleaning agent, to achieve a rapid cleaning effect. |

| Product Tags: LED roll SMT Pick Place Machine SMT Pick And Place Machine 180000cph 0402 Components SMT Production Line |

|

104 Feeders smd mounting machine, 98000CPH SMT Mounting Machine YT20S |

|

Higher Efficiency Surface Light Emitting Diode SMT Mounter for the German Market |

|

YT10S SMT Production Line With Electric Feeder With Double Motor |

|

Led Tube PCB Processing machine HT-F7s high speed SMT Mounting Machine |

|

0201 led light/driver making Machine ETON 10 heads pick and place machine |

|

1850kg Total Weight Pick and Place Machine for 0.5-5mm PCB Thickness at a Competitive |