High precision LED bulb 80000CPH 20pcs heads pick and place machine

|

|

High precision LED bulb 80000CPH 20pcs heads pick and place machine

Product description Pick and place machine, also known as "Mounter" and "surface mount system", is a kind of equipment configured after dispensing machine or screen printing machine. It is a kind of equipment that accurately places surface mount components on PCB pad by moving the mounting head. It is used to realize high-speed and high-precision placement of components. It is the most critical and complex equipment in the whole SMI and production.

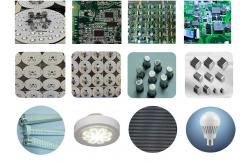

Features 1. Multifunctional pick and place machine, suitable for mounting LED chip, capacitors, resistors, IC, shaped components, lens, etc. 2. Vision system, four cameras, high precision mounting 3. PCB length width: max 450*350mm min80*80mm

Exclusive patented technology

Our advantage 1. We have our own industrial park, covering an area of 520,000 square meters. 2. We have been in this business for over ten years. 3. We have office and local engineer in Egypt, Turkey, India,etc. 4. We can control it remotely, give machine a free upgrade

Application

Package In terms of packaging, we generally use vacuum wooden cases for packaging, which can prevent moisture and protect the machine itself in the process of maritime transportation. Moreover, all the products purchased by customers are placed in one wooden case, so that customers can receive the purchased equipment at the same time and install and produce them in time.

Market Our products are exported to more than 20 countries and regions, including South Korea, India, Vietnam, Tunisia, Egypt, Russia, etc. It is popular in many countries and has gained many big clients. Well regarded.

FAQ Q: Is hard to use these machines? A: No, not at all. All our machine are automatic, you just type in the program and it will work. The operation is relatively simple and I believed that certainly learn in two days.

Q: if there is a problem with the machine,can it be repaired? Of course, the machine failure rate is 0.001 , and in addition to the warranty period, we also provide you with free maintenance 1-2 times a year.

Q:What is the difference between semi-automatic production line and full-automatic production line? A:In short, fully automatic production lines are expensive, but require less labor. Semi-automatic production line is more affordable, but the labor will be more than the automatic line

Q: About technical offer A: As for machine operation, we will arrange engineers to go to your factory for installation and teaching after you buy our machines. If you have engineers who have been involved in the installation of SMT equipment, we can teach you how to install it online.

Q:How can we buy from us? A: Pick and place machine, smt production line, stencil printer, reflow oven, load/unload machine, feeder,nozzle,etc.

|

|

YT10S SMT Production Line With Electric Feeder With Double Motor |

|

Led Tube PCB Processing machine HT-F7s high speed SMT Mounting Machine |

|

0201 led light/driver making Machine ETON 10 heads pick and place machine |

|

Multifunctional High Performance Pick And Place Machine Manufacturers |

|

YT20S SMT Mounter For Ultra Small Chip 0201~40*40mm Large Chip Wider Component Range |

|

0201 Skd High Precision PCB Board Assembly Multi-head SMT Pick and Place Machine |