101 - 110 of 214

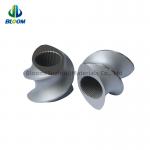

alloy materials parallel twin screw barrel

Selling leads|

...fundamental role in the plastic processing and extrusion process. In a lab twin screw extruder, the screw elements are designed to ensure efficient ...

2025-07-31 00:11:59

|

|

... shear and compression forces essential for homogenization and compounding in extrusion operations. Material 38CrMoAl, CR12MoV=1.2379, W6542, 440C, ...

2025-07-31 00:11:59

|

|

... shear and compression forces essential for homogenization and compounding in extrusion operations. Material 38CrMoAl, CR12MoV=1.2379, W6542, 440C, ...

2025-07-31 00:11:59

|

|

... shear and compression forces essential for homogenization and compounding in extrusion operations. Material 38CrMoAl, CR12MoV=1.2379, W6542, 440C, ...

2025-07-31 00:11:59

|

|

Germany 45 Plastic Extruder Parts Bimetallic Alloy Screw Barrel Screw Element Bimetallic Screw Barrel For LDPE / HDPE / PP / PE / PVC Blowing Molding ...

2025-07-31 00:11:59

|

|

... to protect the extruder screws and barrel from wear and corrosion. It is typically made by welding together two different alloys, a high-wear ...

2025-07-31 00:11:59

|

|

...Twin Screw SZ55/110 For UPVC Water Supply-Drainage Pipe 1 . Material: 38CrMoAIA Nitriding treatment, Surface hardness: HV≥900 Nitriding depth: 0.5...

2024-12-09 20:57:21

|

|

Screw elements are helical components designed to intermesh within the extruder barrels. They facilitate the conveyance, mixing, and processing of ...

2025-07-31 00:11:59

|

|

Screw elements are helical components designed to intermesh within the extruder barrels. They facilitate the conveyance, mixing, and processing of ...

2025-07-31 00:11:59

|

|

Screw elements are helical components designed to intermesh within the extruder barrels. They facilitate the conveyance, mixing, and processing of ...

2025-07-31 00:11:59

|