Shanghai Pullner Filtration Technology Co., Ltd.

|

Shanghai Pullner Filtration Technology Co., Ltd. is a well-known enterprise integrating R&D, production and sales of micro membrane filtration equipment and filtration systems.

Our Main products: Membrane pleated filter cartridge, High flow filter cartridge, Condensate polishing pleated filter element, Condensate polishing string wound filter element, Membrane wound filter cartridge, Melt blown filters, Metal wedge wire filter, Metal sintered mesh filters, Sintered fiber felt filter, and power sintered filters; all kinds oil and gas filters.

Production Plant: We have 10,000 square meters of 100,000-level Clean Room, and more than 10 production lines for various precision filters cartridge. Strict quality control of products, in accordance with international certification standards, At the same time, it is equipped with a well-structured high-level technical R&D and verification team, provide quality products for customers.

Main applications: Biopharmaceutical, food and beverage, microelectronics, fine chemicals, water treatment, laboratory and other fields; covering LCD panels, semiconductor chips, high-purity chemicals, APIs, water reuse, condensate filtration, water reuse etc.

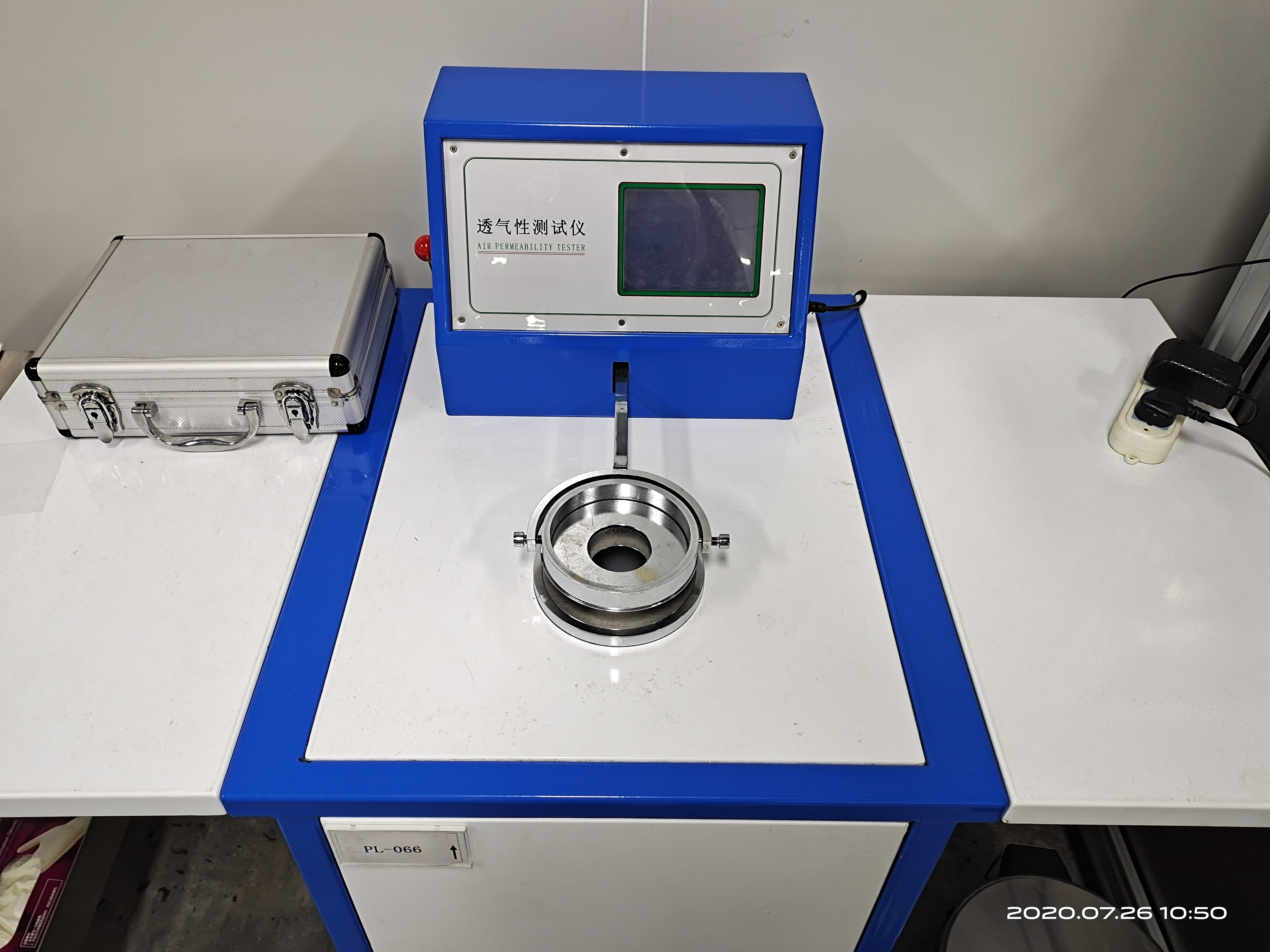

Pullner laboratory: It is equipped with varieties of test facilities: Aperture distribution instrument, water single-pass test bench, scanning electro microscope, bacterial challenge lab, online particle detector, diaphragm test bench, air permeability tester, filter cartridge integrity tester, test trolley for simulating field conditions, etc. With several test experts, quickly provide customers varies conditions solutions.

Pullner Certificates: Our plant has ISO19001, ISO14001, ISO45001 certificates, we are high-tech enterprise with multiple patent certificates. Approval vendor of Saudi Aramco.

Pullner Exhibitions: We have participated in professional exhibitions in the filtration industry all the year round. At the exhibition, we not only met new customers and their product needs, but also gained more understanding of the latest filtration technology and products. For us to improve existing products and develop new Products provide more professional information.

Pullner Packaging and Shipping:

|

- Basic Information

-

Company Name: Shanghai Pullner Filtration Technology Co., Ltd. Business Type: Manufacturer Brands: PULLNER Employee Number: 130~150 Factory Location: 8th Building, No.1132 Maoting Rd., Chedun Town, Songjiang District, Shanghai 201611, China - Trade & Market

-

Company slogan: Shanghai Pullner Filtration Technology Co., Ltd.

OEM Overview: Pullner Provide OEM & ODM service

1. Provide OEM services to many companies at hone and abroad, meet various requirements from production to packing.

2. Our company have sound quality management system and quality tracking system to ensure the long-term stability of our products.

3. The customers can also come to our company for random inspection or come to the company for resident inspection.

Pleated Machine: Pleat height 5mm~40mm, Membrane thickness: 0.1mm~3mm, Max. Width: 1200mm, Max. operating temperature: 150℃. Used in the pleating production process of the high flow pleated filter element. Filter element length: 40”, 60”.

83/130 Welding Machine: Max. operating temperature: 450℃, Max. pressure of cylinder: 6MPa, Used for welding process of the diameter83/130mm filter element.

Laser Marking Machine: Maximum working height 400mm, laser power 20W, Provide customers with customized services, and develop different logos according to customer requirements.

Production Line: Shanghai Pullner Filtration Technology Co., LTD has 10,000 square meters Purification Workshop (100,000-level &10,000-level), and more than 10 production lines for various precision filters cartridge, 6 productions lines for string wound filters, meet customers’ requirement.

Pullner has complete quality control process, which can track the whole process of the production process, the tracking period is 2 years, ensuring high quality products.

Pullner Factory Outside:

Clean Room:

In the purification workshop, workers need to wear purification clothes, purification shoes, masks, hats and gloves. The purification workshop has high requirements on the production environment, which can ensure the cleanliness and safety of the products, and can meet the filtration requirements of food and beverage, biopharmaceutical and other industries.

Pullner Production process:

Our production strictly follow these procedures: Pleating → Seam welding → Assembly → Trimming → Welding → Finished products → Packaging

Main Production Facilities List:

Non-contact infrared welding machine:

the filter cartridge end cover and filter membrane are all heated by infrared, which can ensure the welding strength of the filter cartridge.

Pleated Machine: Pleat height 5mm~40mm, Membrane thickness:0.1mm~3mm, Max. Width: 600mm, Max. operating temperature: 150℃. Used in the pleating production process of the microporous/membrane pleated filter element. Filter element length: 10”, 20”, 30”, 40”.

Pleated Machine: Pleat height 5mm~40mm, Membrane thickness: 0.1mm~3mm, Max. Width: 600mm, Max. operating temperature: 150℃. Used in the pleating production process of the microporous/membrane pleated filter element. Filter element length: 10”, 20”, 30”, 40”.

Cutting Machine: Cutting diameter range: Φ145mm~Φ160mm, power: 2200W. Meet customer requirements for different filter element lengths.

String Wound Machine: Max. operating length: 2000mm, Micron: 0.5μm~50μm, Max. diameter: 80mm. Used to produce string wound filter elements with different micron, length, outer diameter and material.

Ultrasonic Welded Seam Machine: Single welding length 300mm power: 15kHZ

About quality management: Pullner QC

Pullner has a complete ISO quality management system to ensure product quality and traceability. Strict quality inspection and control process, including incoming inspection of raw materials, inspection during production, and ex-factory inspection of finished products, serves as the quality assurance for each product before leaving the factory.

Manpower List for Quality Control Department

S/N

Name

Title

Work Experience

1

Qin Shaofei

QC Manager, Quality Inspector for filter element and Semi-finished products.

4years

2

Liu Lilan

Quality Inspector for filter element

10years

3

Zhou Wanxiang

Quality Inspector for Semi-finished products

1year

4

Ma Wenbo

Material Certificate Inspector

1year

Personnel Responsibility for Quality Department

1. QC manager: Qin Shaofei

He is responsible for all fabrication quality control activities around the company. He shall communicate with other department and quality department.

He is responsible for defining and specify product quality inspection basis and approval standard with the help of technology department.

He shall arrange daily inspection works to all staffs from quality department.

If any quality non-conformance, or quality deviation is found, he has the right to issue NCR to other department, such as procurement depart. Technology depart.

2. Inspector for products: Liu Lilan

Inspectors are arranged in different area. They are responsible for product quality inspection and follow each step. They shall guarantee only qualified product can be marked with “approved” and allowed for delivery. If any defects are found during fabrication, the fabrication shall stop immediately. Inspector shall submit “Un-qualified notes”to related person/depart. If the defect is acceptable, the engineer shall signature his name on the NCR notes and propose his suggestion, such as: scrapping, reuse, or acceptable for normal use.

3. Material Certificate Inspector: Ma Wenbo

He is responsible for material certificate checking and approval. If the material certificate does not meet the requirement listed on datasheet. He shall send feedback to procurement.

Training Records for QC department

Punller has developed an annual training plan for the quality inspection department, including induction training for new employees, regular technical training for all quality inspectors, technical training together with technical department for new products, and temporary training for quality problems.

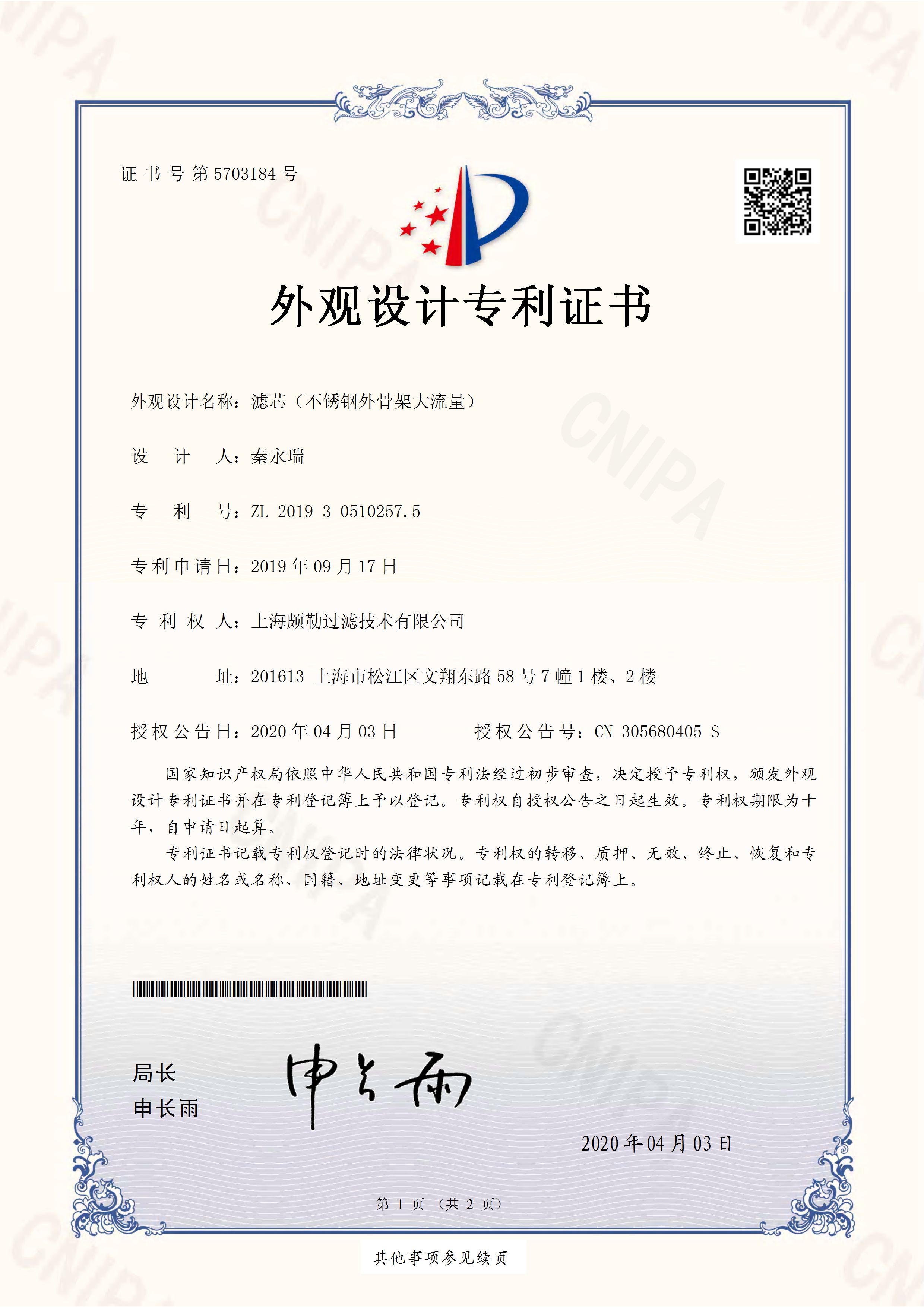

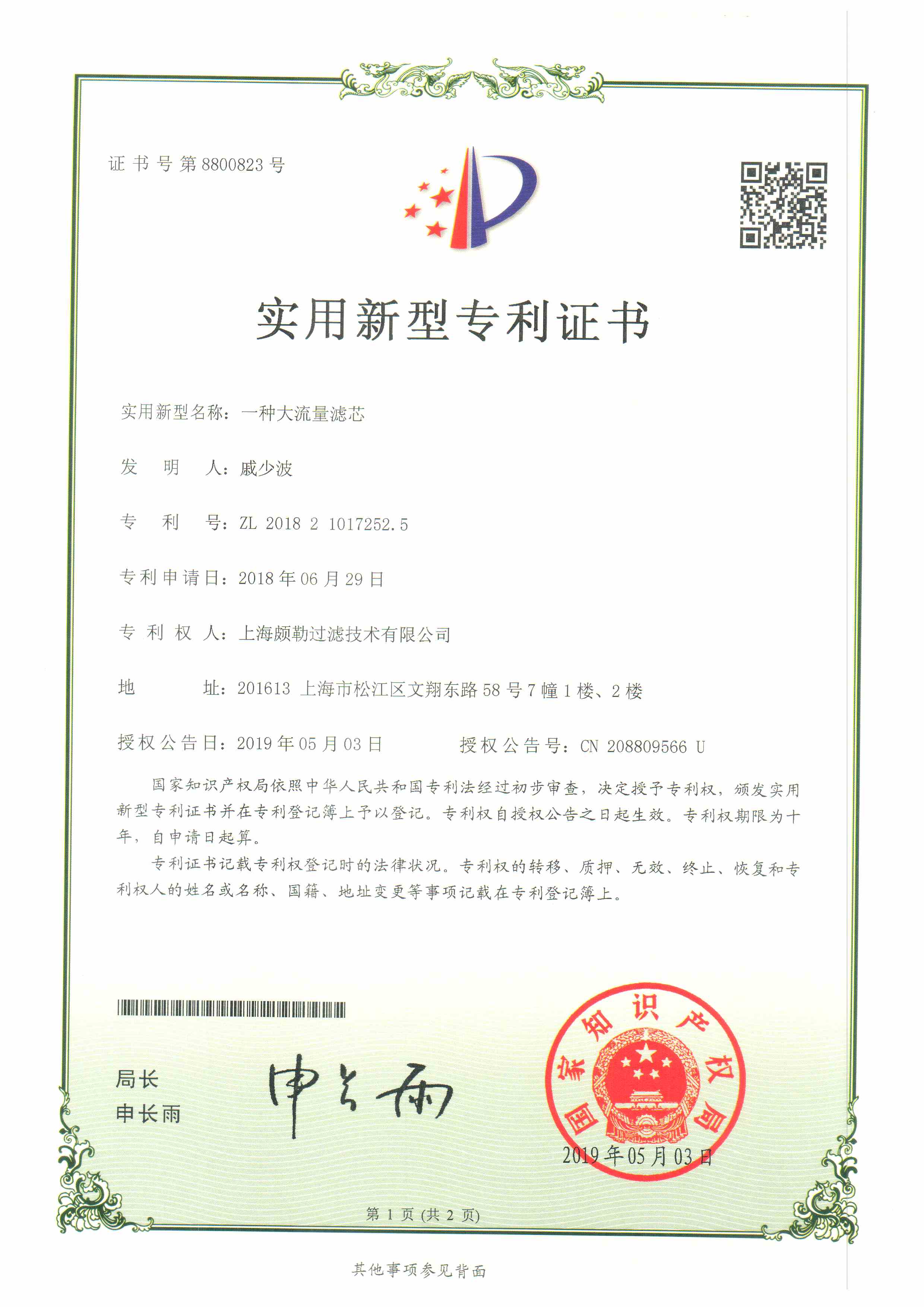

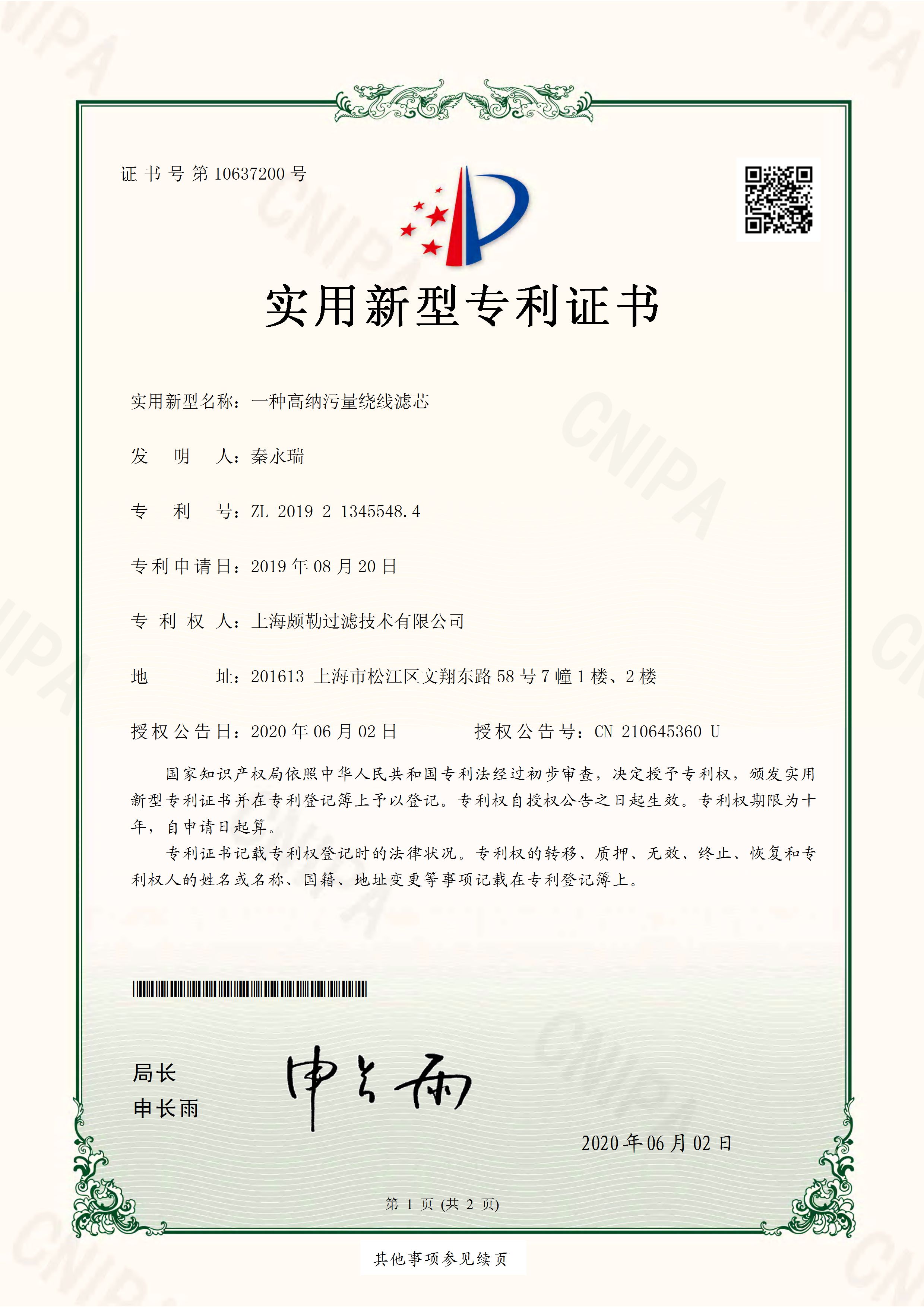

Certifications

ISO 9001 ISO 14001 ISO 45001

High-tech Enterprise Certificate

Pullner Patents

Services: Technical Department Information:

The technical department is equipped with professional technical team, and the technicians have rich experience in design, research and development, and field service experience. The modern laboratory has advanced inspection and testing equipment to meet the needs of new product development and sample and filter material testing. The technical department provides detailed drawings, improve the process control of products and improve product quality. Strictly select the ratio of raw materials to achieve the best filtration effect.

Responsibilities:

Answers to early technical questions and sorting out technical data;

New product design and development, production process control;

Technical standard setting;

Product improvement, drawing refinement and production process considerations;

Negotiate technical agreement and cooperate with the sales department for quotation.

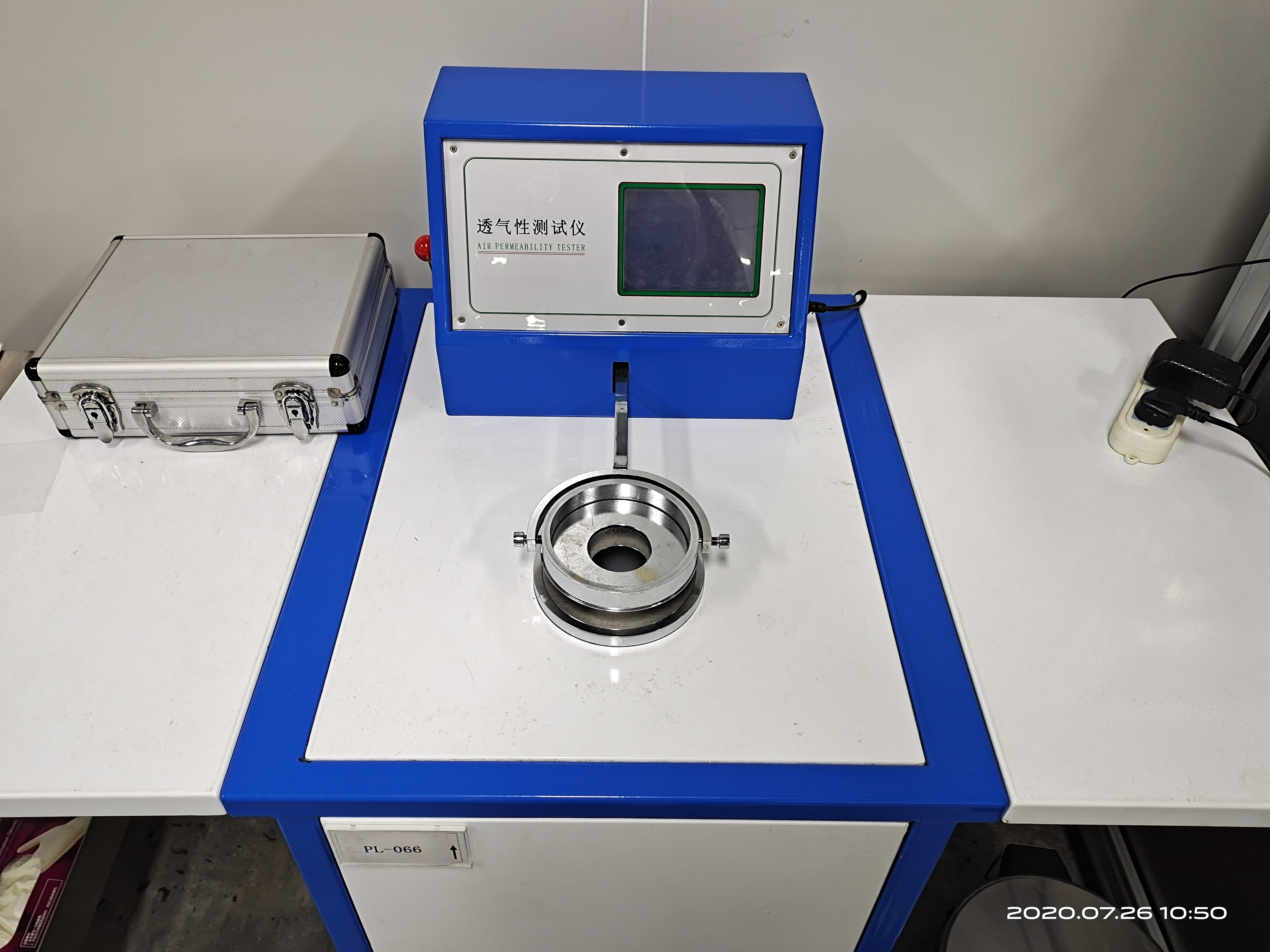

Pullner Laboratory

It is equipped with varieties of test facilities: Aperture distribution instrument, water single-pass test bench, scanning electro microscope, bacterial challenge lab, online particle detector, diaphragm test bench, air permeability tester, filter cartridge integrity tester, test trolley for simulating field conditions, etc. With several test experts, quickly provide customers varies conditions solutions.

Test Facilities List:

1. Single-Pass Test Bench

Description:

The application condition is the removal of solid impurities from water or oil. The filter material is initially screened by a general-purpose method. At this time, the designer will conduct an in-depth analysis and comparison of the appropriate filter material to understand the actual resistance of the filter material, filtration efficiency, pollution holding capacity and other important parameters.

Technical Parameter:

Function

used to test the resistance, filtration efficiency and dirt holding capacity of the filter material or filter cartridge.

Experimental standard

EN13443-2

Experimental flow (filter material)

0.5-10L/min

Experimental medium

water

Particle size range

1~80um

Scope of application

It is used for the working condition of liquid-solid separation filter cartridge with water medium and filtration accuracy ≥1um.

2. Permeability Tester

Description:

Permeability Tester is used to test the air permeability of various filter materials such as filter membrane, filter cloth and filter paper.

Meet the standard: GB/T5453 GB/T13764

Technical Parameter:

Pressure range

0~4000Pa Self-setting pressure drop A

Nozzle

Total 11pcs

Power

AC 220V±10V 50Hz

Power consumption

2000W

Weight

80Kg

Dimension

600*700*1100(L*W*H)

Sample area

5cm2 ;20 cm2 ;50 cm2 ;100 cm2

Measurable air permeability

0.1~12000mm/s

3. Bubble Point Tester

Description:

The bubble point tester is used to detect the bubble point of the filter element, and can test the initial bubble point of the filter element and the group bubble point of the filter element.

Technical Parameter:

Working medium

Industrial ethanol Isopropanol

Preset Pressure

15KPa

Filter Element Length

100mm-2000mm

Power

AC220V 50HZ

Rated Power

0.75KW

Pressure regulation

20-50Pa

4. PMI Capillary Flow Porometer

Description:

PMI Capillary Flow Porometer is advanced porous material pore size analysis instrument, using methods such as gas permeation method (also known as capillary flow method or bubble point method), through this equipment, we can get accurate and repeatable data, can accurately measure Important through-hole characteristics of porous materials, such as minimum pore size, maximum pore size (bubble point), pore type distribution, average pore size and other data.

Technical Parameter:

Standard

ASTM 316

Test principle

Capillary flow method(Gas permeation method)

Minimum test aperture

0.06μm(60nm)

Maximum test aperture

500μm

Pressure range

0-100PSI

Sample size

Sample diameter 10mm~50mm, Max. thickness is 35mm.

Flow resolution

1/60000

5. Integrity Detector

Description:

The automatic filter integrity tester is a special instrument for integrity testing of the sterile grade filter material of the terminal and the process. It can perform bubble point, diffusion flow, water immersion and pressure decay tests. The instrument can be tested first and online, which can judge whether the filter material is qualified or not, and also check whether the filter housing and seals are intact. The test does not affect the sterility of the downstream. This instrument is suitable for the integrity test of sterilization filters in industries such as biology, medicine, food and beverage.

Technical Parameter:

Testing Method V1: Bubble point, diffuse flow, pressure holding method

V2: Bubble point, diffuse flow, pressure holding method, water immersion method

Test Range Automatic Testing:

Bubble point method:0.05MPa-0.6MPa

Pressure decay:0-0.6MPa

Diffuse flow 0-2000ml/min

Water immersion 0-100ml/min

Manual test:

0-0.6MPa

Gas source Clean and dry air or nitrogen(3000Mbar-9000Mbar) Power AC220V 50HZ Rated Power <150W Operating temperature 0-40℃ Weight 5.1Kg 6. Multi-Pass Test Bench

Description:

As an important equipment for evaluating the performance of hydraulic transmission filter elements, the test bench is used to test the filtration accuracy of the filter element. Secondly, the service life of the filter element can be indirectly tested by analyzing the index of the filter element's dirt holding capacity. At the same time, it has passed the test many times. The platform can also test the pressure drop variation range during the service life of the filter element to reflect the product's oil flow ability to evaluate the impact on the normal operation of the hydraulic system.

Technical Parameter:

Test performance Filtration efficiency, liquid PQ curve, dirt holding capacity Test dust ISO A3 dust Testing standard ISO 16889-2008 Hydraulic transmission filter Multi-pass method to evaluate the filter performance of filter element Pressure range 0-1.6MPa Flow range 0.5l/min-5.0l/min

5.0l/min-50.0l/min

40.0l/min-140.0l/min

Dirt injection flow 50ml/min-300ml/min Online dilution system dilution ratio 1: 5~10 Test cycle, sewage injection mixing system temperature 40℃±1℃ 7. Inductively Coupled Plasma Mass Spectrometer

Description:

Measure the content of various metal ions in the solution through collision and reaction gas impact on the ions in the solution after materialization, and qualitatively analyze the content of liquid metal ions.

Technical Parameter:

Organic Oxygen Plus Circuit Standard Collision Reaction Cell Gas Path 3 lines Usable Collision Reaction Gas He H2 O2 CH4 NH3 Testing Facility Triple Quadrupole Determination Of Elements No.5-95 element Whether It Can Measure High Matrix Samples Yes Product Size 81*69*75cm Test Accuracy 0.1ppt 8. Particle Sensor

Description:

Quantify the number of particles in the solution by drawing a quantitative solution and measuring the number of internal particles.

Technical Parameter:

Light Source Laser diode(Wavelength 780nm,Rated output 40mW) Material Of Parts In Contact With Sample KS-42BF: Sapphire PFA PTFE Flow Rate 10mL/min Predetermined Area 0.2 um-2 um Particle Size Range (5 Channels, Factory Default) ≥0.2um, ≥0.3um, ≥0.5um, ≥1um, ≥2um Maximum Number Of Particles Concentration 1200pcs/mL(The error value is lower than 5%) Power Supply DC12 V(supply from KE-40B1) Size and weight Size: 125(H)*240(W)*151(D)mm, Weight: 3.2Kg 9. Electronic balance

Description:

The electronic balance is used to measure the weight of the filter membrane per unit area. The balance that uses electromagnetic force to balance the gravity of the weighed object is called an electronic balance, which is characterized by accurate and reliable weighing, fast display cleaning, and has an automatic detection system, a simple automatic calibration device and an overload protection device.

Technical Parameter:

Range 120g Readability 0.1Mg Weighing pan size 90mm Repeatability ≤±0.1mg Linear ≤±0.2mg Calibration method External verification Our Team: Pullner Team:

Pullner brings relevant professional top talent and technology together for a highly qualified professional team. We have R&D Dep., QC Dep., After-sale service Dep., Production Dep., and Sale Dep., as the expansion of our business, we welcome more friends.

Training is a core course for all the members and we will organize various trainings to help us to improve our abilities and Let us find the beauty of life. We treasure the time we are learning and studying together.

At the begining of every month, we will set our own goals and set the awards in advance. If any group achieve their goals, they can enjoy their rewards which only belongs the winner. Colorful ourdoor activities. Enjoy your life.

Pullner Clients:

Feedback from Clients:

- Factory Information

-

Market name: Worldwide Contact Person: Miss.Lucy Contact Phone: 86-021-57718597