Carbide Micro End Mills And Short Flute Length Various Materials Machining

|

Product Description:A micro diameter end mill refers to an end mill with a very small cutting diameter. These end mills are specifically designed to produce extremely fine and precise cuts in materials. Micro diameter end mills typically have cutting diameters ranging from a few micrometers (μm) to a few millimeters (mm). The exact size can vary depending on the specific application and machining requirements. These end mills are much smaller in diameter compared to standard end mills used in general machining operations. The smaller cutting diameter of micro diameter end mills allows for the creation of intricate features and fine details in workpieces. They are often used for milling small channels, slots, holes, and contours in materials like metals, plastics, composites, and ceramics. To ensure optimal performance, micro diameter end mills are engineered with high precision and may feature specialized geometries and coatings. They are typically made from materials that offer high hardness and wear resistance, such as solid carbide or high-speed steel. Multiple flutes may be incorporated to improve chip evacuation and achieve better surface finishes. Micro diameter end mills are commonly used in CNC milling machines and micro-machining centers, which provide the necessary rigidity and precision for working with such small cutting tools. These tools require careful handling and proper setup to achieve the desired results. In summary, micro diameter end mills are designed for ultra-precise machining operations, where the creation of small and intricate features is required. They enable the production of miniature components with tight tolerances and are widely used in industries that demand high precision and fine detail. Applications:Common Application of Carbide Micro Diameter End Mills Carbide micro diameter end mills are widely used for various purposes due to its capability to produce high precision and intricate parts with fine details. They are adopted in different industries for various purposes. Electronics Carbide micro diameter end mills are used in the electronics industry for manufacturing various components, such as circuit boards, microelectromechanical systems (MEMS) and more. They are suitable for creating small features, such as microvias, fine traces, and intricate patterns on electronic substrates. Medical Devices In the medical device industry, micro diameter end mills are used to manufacture miniature components and devices. They are suitable for machining surgical instruments, implants, dental components, and microfluidic devices, which require a high degree of precision. Aerospace In aerospace applications, micro diameter end mills are crucial in the production of small, lightweight components. They are used for machining intricate features in aerospace alloys, composites, and advanced materials. Micro-optics Micro diameter end mills are employed in the creation of small optical components like lenses, mirrors, waveguides, and optical fibers. They are suitable for precisely shaping and machining these miniature optical elements. Watchmaking and Jewelry Carbide micro diameter end mills are used to carve intricate designs, engravings and fine details on watch components, jewelry pieces, and gemstone settings in the watchmaking and jewelry industries. Precision Machining Micro diameter end mills are significant in the field of precision machining. They are capable of creating small features, slots, and contours in different materials, including metals, plastics, composites, and ceramics. Automotive These end mills are also used in the automotive industry for the production of small parts and components with tight tolerances. They are applicable for manufacturing fuel injectors, sensors, connectors, and other intricate automotive components. Microfluidics Micro diameter end mills are essential for machining microfluidic channels, chambers, and structures employed in lab-on-a-chip devices and microreactors. These devices are widely used in the life sciences, diagnostics, and drug discovery fields. Customization:Micro End Mills

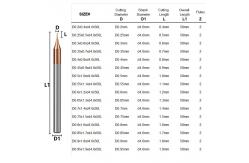

Features: Micro grain milling cutter, 0.1MM-0.9MM High Quality Carbide micro flat end mill for Steel Brass Milling, 0.2mm micro ball nose end mill 2 flutes, 4mm shank. Support and Services:Technical Support and Service for Micro End Mills

Packing and Shipping:Packaging and Shipping for Micro End Mills:

FAQ:Q1: What is the brand name of Micro End Mills? A1: The brand name of Micro End Mills is SUPAL. Q2: What is the model number of Micro End Mills? A2: The model number of Micro End Mills is Micro Diameter. Q3: Where is the place of origin of Micro End Mills? A3: The place of origin of Micro End Mills is Changzhou, Jiangsu, China. Q4: Is the Micro End Mills certified? A4: Yes, the Micro End Mills is certified with ISO9001. Q5: What is the minimum order quantity of Micro End Mills? A5: The minimum order quantity of Micro End Mills is 10pcs. |

| Product Tags: 50mm Micro End Mills Carbide Micro End Mill Bits Short Flute Carbide Micro End Mills |

|

30 Degree Helix Angle Micro End Mill For Delicate Precision Machining |

|

Carbide Micro End Mills And Short Flute Length Various Materials Machining |

|

Square / Ball Nose Micro End Mills 2 Flutes Shank Diameter 4mm |

|

Square Cutting Edge 0.2mm Micro Ball Nose End Mill 2 Flutes 4mm Shank Diameter |

|

4mm Shank Diameter Carbide End Mill For Various Applications |

|

Wear Resistace Micro End Mills With Original Material 1-20mm Diameter |