61 - 70 of 85

hip sintering tungsten carbide button

Selling leads|

... into a billet, heating it to a certain temperature (sintering temperature) in a sintering furnace, and maintaining it for a certain period of time ...

2024-12-09 12:27:07

|

|

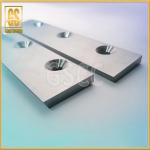

Tungsten Carbide Cutting Tips With Hole,Carbide Hardware Tools, Plastic Cutters, Paper Cutters, Aluminum Cutters, Etc. The cemented carbide is formed ...

2025-07-27 00:08:50

|

|

... inserts are precisely machined from specific blanks 2. Primary ultrafine particles 3. Spray granulation 4. TPA compression molding 5. Solid ...

2025-07-27 00:08:50

|

|

... and Co cobalt powder through powder milling, ball milling, pressing and sintering by metallurgical methods. The main alloy components are WC and ...

2025-07-27 00:08:50

|

|

... process, which is beneficial to remove impurities, improve the purity of the sintering atmosphere, improve the wettability of the binder phase, ...

2025-07-27 00:08:50

|

|

The main process flow of cemented carbide round bar: Milling → Recipe according to the application requirements → wet grinding → mixing → pulverizatio...

2025-07-27 00:08:50

|

|

... in vacuum or Hydrogen reduction furnace with refractory tungsten material (WC) micron powder as the main ingredient and Cobalt (Co), Nickel (Ni) ...

2024-12-09 12:28:54

|

|

Tungsten steel sintering process The classification of tungsten steel is carried out according to ISO standards. This classification is based on the ...

2024-12-09 12:27:07

|

|

It is widely used as a high-speed cutting tool, kiln structural material, jet engine parts, cermet materials, and resistance heating elements. It is ...

2024-12-09 12:27:07

|

|

The cemented carbide is formed by powder metallurgy, heated under vacuum, and undergoes the vacuum dewaxing sintering process, which is beneficial to ...

2025-07-27 00:08:50

|