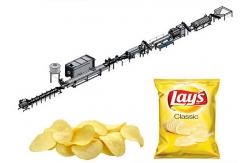

100kg/H Pringles Potato Chips Complete Production Line

|

100kg/H Pringles Potato Chips Complete Production Line

potato chip maker processPotato Washing -- peeling—cutter—washing—blanching—dewater machine—drying line--pre-fry—deoil machine—cooling line-- frozen--packed --store in cold room Washing process: The washing process is for washing off the potato starch on the potato chips which can keep it from fall in the oil and keep long-use life for the frying machine. At the same time, the potato chips is totally immersed in water which can keep it from enzymatic-oxidative browning, because the sugar can be affected with amino acid and the produce the black and brown color Blanching process: Blanching is a necessary procedure. After washing, the potato sticks go into the blanching machine which is about 65-90 ℃hot water. It can destroy the enzyme activity, and improve and soften the organizational structure which can be easily dried and also can keep from blistering. It can add the Sodium hydrogen sulfite or Sodium pyrosulfite to keep the good color. Prefrying: frying temperature is about 180-190 °C, and the frying time is about 1 minute. The higher the content of dry and starch, the lower oil content for the potato chips. The inner is soft and outside is crisp. Freezer and cold room:-18 - -25℃ Packing size and weight is based on customers’ requirement Packing machine: 520, 720 Frying For final customers The frying time for frozen French fries before eating is about 3 minutes at 168 ℃ of oil temperature. The oil content is about2.5%-4.3% Beef tallow: it is the best oil for frying potato chips and french fries. It is very incensed and of low melting point( vegetable oil is of higher melting point which is drying on the surface. Palm oil: good for health, cheap and white

We Provide Satisfied Service & Turnkey Solution b.) Project planning and design service; c.) Debugging of equipment until everything is functional; d.) Management of equipment' long distance shipping from seller's factory to the named place by buyer; e.) Training of equipment maintenance and operating personally; f.) New production techniques and formulas; g.) Provide 1-year complete warranty and life-time maintenance service. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

150kg/H Compound Pringles Fresh Potato Chips Production Line Stainless Steel 304 |

|

High Efficiency Curly Potato Chips Production Line SUS304 Material |

|

Commercial Auto Freeze French Fries Machine/French Fries Production Line |

|

100kg/H Pringles Potato Chips Complete Production Line |

|

30kg/h wave type potato chips production line |

|

Most Advanced Technology Potato Crisps Processing Machine |