The material selection of the punch pin is mainly high-speed steel. The commonly used materials are SKH9, SKH55, SKH59 in Japan, M2, M35 and M42 in the United States. The main feature of the material is that the high-speed punching material can maintain good red hardness and wear resistance. There are also some powder high speed steel materials, commonly used are ASP23, ASP30, ASP60. The performance of the material is superior to that of high-speed steel, but the price is high and the range of use is relatively small. Tungsten carbide punch pins are new products that can be produced by a few companies this year. They are mainly made of tungsten carbide. They have high toughness requirements for materials, and the technical requirements and production costs during production are also high. They are commonly used in the stainless steel cold heading industry.

Customized Precision SKD11 0.001 Mm Precision HSS Punch H9 H55 Pin Punch

|

Detailed Product Description

|

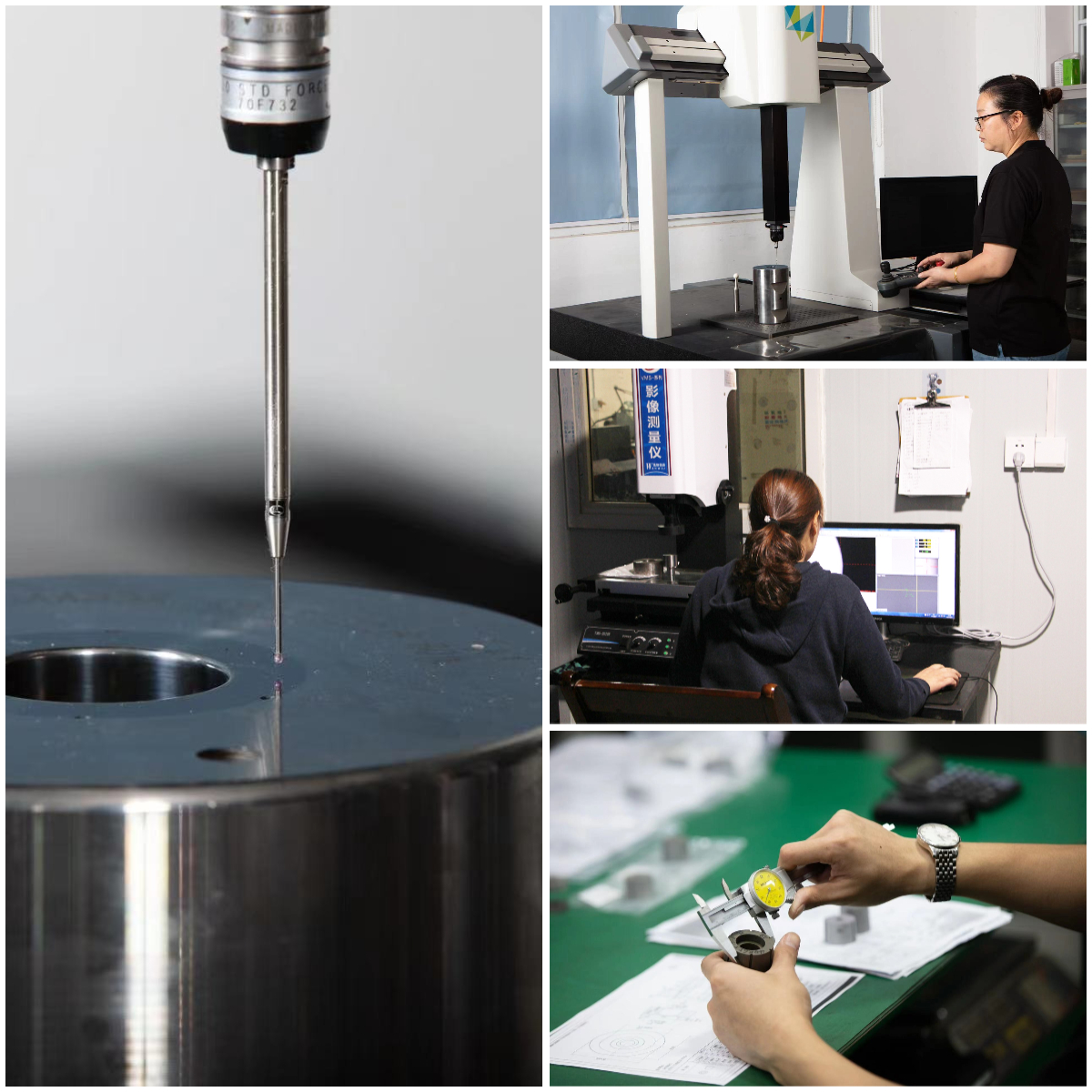

China Customized OEM Precision SKD11 0.001 mm Precision HSS Punch H9 H55 Pin Punch Products Description HSS Punch Material: Carbide>M42(H59)>M35(H55)>M2(H9) Surface Treatment: TILAN Factory About Us Chongqing Henghui Precision Mold Co., Ltd. has CNC lathes, CNC machining centers, CNC Cylindrical Grinding Machine, CNC EDM machine, CNC Cutting Machine, Milling Andam Drilling Machine ,etc.We also have various types testing equipment,such as Rockwell Hardness Tester, Projector ,3D Image Measuring Instrument, etc. Henghui using high-quality tungsten carbide material and professional vacuum heat treatment.We design,manufacturing and supply high-quality precision molds for customers who engaged in cold heading and hot upsetting industries.About our molds , the relative standard deviation can be controlled within 0.005mm, concentricity can be controlled within 0.01mm. Strict accordance with ISO9001:2015 quality management system requirements of the operation,can ensure provide timely and high-quality service for our customers.Our products has exported to Southeast Asia,Europe and the United States ."Customer first, quality first, technology first, dedicated service" is our consistent operating principles.Warmly welcome to negotiate business with us. Exhibition Exhibition, German Fastener Exhibition, Indian Fastener exhibition and so on. We are committed to participating in various fastener screw exhibitions, and we have gained many new friends in the exhibitions. At the same time, we will visit our new and old customers offline. In each exhibition, we prepared various samples carefully and waited for the exhibition customers, who were satisfied with our products no matter in terms of design, price or quality. Packing and Delivering Packaging Details:Carton Box; Export Standard Package, Or As Client's Requirement. Delivery Detail:According To The Quantity Of The Order, About 12-45 Days. Inspection equipment FAQ Q1: How can I get a quotation from your company? A1: Contact us.In order to quote you as soon as possible, we need the following information: drawings, Material , Quantity ,Surface treatment. Q2: What is our lead time? A2: This will be based on the number of products you customize and the country you are in. |

| Product Tags: 0.001 mm HSS Punch Precision SKD11 HSS Punch SKD11 HSS Punch |

Related Products

|

High Precision HSS Carbide Punches And Dies Punch Pin OEM Design Screw Die Parts |

|

2025 New Design Cold Heading Process TiN Coating Punch Pin With M42 And H59 HSS Punches High Red Hardness Wear Resistance |

|

New Design Carbide Die Cutting Punch Pins High Speed Steel Punch Die Pin Punch |

|

Customized Punch Pin High Wear Resistance Enhance Your Cold Heading Process With M42 And H59 HSS Punches |

|

Enhance Your Cold Heading Process With M42 And H59 HSS Punches High Red Hardness Wear Resistance |

|

Customized Precision SKD11 0.001 Mm Precision HSS Punch H9 H55 Pin Punch |

Email to this supplier