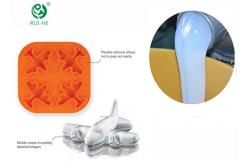

Low Shrinkage Liquid Silicone Injection Molding OEM / ODM For Cake Molds

|

|

WIth FDA Certificate Low Shrinkage Liquid Silicone Rubber Injection Mold For Cake Molds

Description

LSR RH6250 -10 A / B is food grade liquid silicone rubber for injection molding processes.

Food grade silicone rubber offers the strength and stress resistance required to manufacture baking trays, bottle dispensers, and other products for the kitchen and throughout the home. LSR RH6250 -10 liquid silicone rubber are platinum cured (vulcanized) materials which are mixed in a 1: 1 ratio by weight.

Key Features and Benefits

Vulcanisates consisting of RH6250 -10 are distinguished by the following properties:

Typical Properties

These figures are for reference only, please contact us for details.

Typical properties of the vulcanisate: The mixing ratio of components A: B = 1: 1. Vulcanization: 5 min. 150 °C (302 ℉)

Details

Applications

Because of the outstanding properties, RH6250-10 A / B Lquid silicone rubber is particularly suitable for the following elastomeric articles: baking molds and trays, ice trays, casting butter, chocolate, fondant, baby products, and kitchen utensils etc.

Certificate

Rui-He RH6250-10 Liquid silicone rubber obtained the following test certificate: Rohs, FDA, MSDS, LFGB, Paths,....ETC.

Notice

This product cannot be contacted with compounds containing N, P, S to avoid affecting the catalytic effect of platinum.

Application & partner Brands

Operation way about FDA platinum cure silicone rubber for candy mold/ any mold/cake mold

1. Please clean your original model(mother model) before you begin your mold making operation.

2. Weigh a suitable amount of RUI-HE silicone.

3. Mixing the two parts by the ratio of 1:1/10:1 and mix part A and part B evenly in 2-3 minutes.

4. And get the mixture for vacuum-pumping for de-air the bubble in about 2-3 minutes.

5. Fix the mother model onto a clean wooden board.

5. Build a mold frame with four plastic plates or wooden plates, sealing the gap.

6. Release agent should be applied onto the products’ surface.

7. Pour the vacuumed mixture into the model frame from the side of the mold frame.

8. When the silicone mixture gets cured, a clear silicone mold will come out.

Why You Need to Choose RUI-HE?

1. Long history and solid foundation With 15 years of development history and good reputation, our products are exported to 138 countries around the world.

2. High-end research and development Being a leading liquid silicone manufacturer in China, we have a professional R&D team and QC team, and our product is FDA, SGS, RoHS, MSDS, FDA, ISO, REACH, UL approved, so there is no need to worry about the quality.

3. Efficient service We have a professional sales team who will solve your problems patiently. Besides, with the efficient logistics distribution system, you could get you goods earlier. Last, good after-sales service, we build long term cooperation relationship, once there is a quality problem, we could solve right away.

If you need to know the prices of our silicone rubbers, please contact us. We do not provide prices in the website because prices fluctuate for many reasons.

|

||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: food grade silicone mould making rubber food safe silicone rubber | ||||||||||||||||||||||||||||||||||||||||||||

|

|

Non Toxic Transparent And Soft Food Grade Silicone Rubber With 20-70 Shore A Hardness |

|

|

Eco Friendly Liquid Silicone Rubber With 20-70 Shore A Hardness And Temperature Resistance |

|

|

Food Grade Rubberized Silicone With Viscosity 1000-100000 Cps |

|

|

Transparent Food Grade Liquid Silicone Rubber 20-70 Shore A Hardness For Food Contact |

|

|

Food Grade Non toxic Liquid Silicone Rubber With Temperature Resistance -60\u2103~200\u2103 |

|

|

Food Grade Transparent Liquid Silicone Rubber 1000-100000 Cps Viscosity -60℃ To 200℃ Temperature Resistance |