Precision Fabricated Sapphire Rod High Purity Single Crystal Sapphire Component

|

Introduction of Sapphire Rod

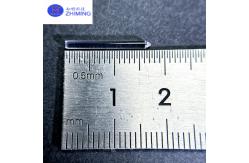

The Sapphire Rod is a precision-fabricated, high-purity single-crystal sapphire component designed to meet the demanding requirements of advanced optical, mechanical, and scientific applications. Crafted from single-crystal aluminum oxide (Al₂O₃), this rod exhibits exceptional hardness, optical transparency, thermal stability, and resistance to wear, corrosion, and high pressure. What sets this particular sapphire rod apart is its customized geometry, including a finely tapered or conical tip—indicating it is designed for niche applications requiring both dimensional accuracy and extreme durability. With a hardness second only to diamond (Mohs 9), sapphire rods are often chosen over glass or quartz in high-stress environments where failure is not an option. These rods are widely used across multiple industries such as aerospace, semiconductor processing, metrology, photonics, biomedical devices, and high-temperature processing, where consistent performance under extreme conditions is required.

Production Principle of Sapphire Rod

The manufacturing of a sapphire rod involves advanced crystal growth and precision machining technologies to ensure exact specifications and defect-free surfaces. The two most common methods used to grow sapphire crystals for rod production are:

1. Kyropoulos (KY) MethodThe KY method is widely adopted for growing large, high-quality bulk sapphire crystals. It involves slowly pulling a seed crystal from molten aluminum oxide (Al₂O₃) inside a high-temperature furnace. The process is carefully controlled to regulate the temperature gradient, pulling rate, and rotational speed, producing an optically isotropic and structurally stable sapphire boule. Once solidified, the sapphire boule is oriented, cut, and machined into rods.

2. Edge-defined Film-fed Growth (EFG) MethodThe EFG method is ideal for producing sapphire rods, tubes, and profiles with pre-defined shapes. In this technique, a die (or shaper) is submerged in a crucible filled with molten sapphire. The molten material is drawn upward through the die by capillary action and crystallizes into a solid rod. This allows for continuous production of rods with tight dimensional tolerances and minimal post-processing.

After crystal growth, the sapphire rods are cut to length using diamond saws and polished using ultra-fine abrasives to achieve optical-grade finishes and precise geometrical features like sharp or rounded tips, grooves, or step transitions.

Sapphire Rod Features of Sapphire Rod-High Strength, High Rigidity, High Anti-Abrasion, High Anti-Heat, High AntiCorrosion Characteristics, and High Anti-Plasma Characteristics. Because of these characteristics, Single Crystal Sapphire is widely used for precision mechanical parts. -Stable Dielectric Constant, Very Low Dielectric Loss, Good Electrical Insulation. Single Crystal Sapphire is used as a material for substrates in super-high frequency regions. It is also used as an insulation material and microwave window. Single Crystal Sapphire has become indispensable in the Electronics Industries. -Excellent Light Transmission. Single Crystal Sapphire is used for various kinds of vacuum equipment, windows in reaction furnaces, scanner windows, and caps for optical communication due to its excellent mechanical characteristics and heat resistance. -Good Thermal Conductivity and High Heat Resistance. Excellent thermal conductivity at low temperatures allows Single Crystal Sapphire as a transparent material to be used in many diverse fields requiring thermal conduction and heat radiation.

Paramete of sapphire rod

Applications of Sapphire Rod

Sapphire customized rods are deployed in a wide variety of cutting-edge fields due to their unique combination of physical, thermal, and optical characteristics:

1. Semiconductor and Electronics

2. Scientific Instrumentation

3. Optical Systems

4. Biomedical Devices

5. Aerospace and Defense

6. High-Temperature Environments

Frequently Asked Questions (FAQ) of Sapphire Rod

Q1: What makes sapphire rods superior to quartz, glass, or ceramic

rods?

Q2: Can the sapphire rod be customized in shape, length, or

diameter?

Q3: Is the sapphire rod optically polished or just mechanically

ground?

Q4: What kind of environments can sapphire rods operate in?

Q5: Are these rods compatible with infrared or ultraviolet systems?

Q6: How long does it take to produce a custom sapphire rod?

Q7: What tolerances can you achieve?

Related products

Ruby Rod Laser Technology Medical Instruments Made From Synthetic Sapphire Dia 1×7cm

Customizable Sapphire Irregular Rod Industrial Special-purpose Applications High Hardness

About Us

ZMSH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.

Packaging & Shipping Information

Packaging Method:

Shipping Channels & Estimated Delivery Time:

UPS, FedEx, DHL

|

||||||||||||||||

| Product Tags: Component Sapphire Rod Precision Fabricated Sapphire Rod High Purity Sapphire Rod |

|

Precision Fabricated Sapphire Rod High Purity Single Crystal Sapphire Component |

|

High Pressure Sapphire Capillary Tubes High Precision Hollow Microstructures Fabricated |

|

High Performance Sapphire Capillary Tubes Thermal Shock Resistance |

|

|

Sapphire Lift Pin For Semiconductor Ceramic Lift Pins High Purity Sapphire Pins |

|

Dia 10mm Sapphire Components Polished Al2o3 Single Crystal Sapphire Drive Pipe |

|

Polished Al2O3 Crystal Sapphire tube , Sapphire Cup Tube Pipe Industrial |