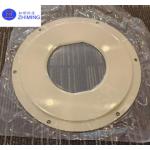

SiC Ceramic Fork Custom Made Precision Structural Component Handle Wafers Optical Component

|

|

SiC ceramic fork custom-made precision structural component, handle wafers, optical component

Abstract of SiC ceramic fork

SiC Ceramic Fork Arm is a structural component made from advanced silicon carbide ceramic material. It is primarily used in precision equipment requiring high rigidity, low thermal expansion coefficient, and high wear resistance. The "fork arm" shape is commonly found in high-end optical devices, semiconductor processing equipment, and automated handling systems, serving as a support, positioning, transmission, or clamping element. Compared to traditional metal materials, silicon carbide ceramic offers significant advantages in mechanical performance, thermal stability, and corrosion resistance, and has gradually become a key functional component in modern high-precision manufacturing.

Attribute table of SiC ceramic fork

Design and Manufacturing of SiC Ceramic Fork Arms

Structural Design

SiC fork arms are custom-designed according to application requirements. Common forms include "U-shaped" or "T-shaped" arms used for:

Key considerations in design include:

Processing Techniques

The manufacturing process involves several critical steps:

Process Flow Diagram for Preparation of SiC Ceramic Components

Application Scenarios of SiC ceramic fork

Semiconductor Equipment

SiC ceramic fork arms are commonly used in wafer handling systems for processes such as photolithography, etching, and packaging. Advantages include:

Used in:

Optical Systems & Telescopes

In high-precision optical instruments, SiC fork arms provide:

They are often used in:

Aerospace & Defense of of SiC ceramic fork

In aerospace systems, SiC fork arms are valued for

Typical roles include payload supports, gimbal linkages, and optical mounts.

Robotic & Automation SystemsIn cleanroom automation environments, SiC fork arms are used as end-effectors or grippers, offering:

Customization & Technical Support

As a non-standard precision component, SiC ceramic fork arms are typically customized based on user requirements. Customizable parameters include:

We support full-cycle services including drawing review, FEM simulation for mechanical behavior, and prototype verification to ensure performance and compatibility.

Related products

6 Inch Silicon Carbide SiC Coated Graphite Tray High Temperature Resistance Graphite Plates

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: custom made SiC ceramic fork SIC ceramic handle wafers SiC ceramic precision structural component |

|

SiC Ceramic Fork Custom Made Precision Structural Component Handle Wafers Optical Component |

|

|

Silicon Carbide Trays SiC Wafers Tray Plate For ICP Etching MOCVD Susceptor Wear Resistant |

|

SiC Ceramic Tray Plate Wafer Holder For ICP Etching Process In Epitaxial Growth Processing |

|

Alumina Ceramic / Mechanical Arm / Suction Cup / Ceramic Structural Parts Al2O3 |

|

|

Silicon Carbide Ceramic Tray Used To Support Materials Semiconductor Wafers Excellent Corrosion Resistance |

|

|

Silicon Carbide Ceramic Tray With CVD SiC Coating Size Customized High-temperature Sintering |