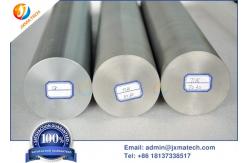

Titanium Aluminum Alloy Rod for Sputtering Target (TiAl) alloy

50:50/ 70:30 at%Titanium Aluminum Alloy Rod Diameter 80mm, 90mm , 100mm x L ,

which can be cutted to machine to the final size sputtering target

After the development of sputtering coating technology in recent

years, the coating technology for various materials has been very

perfect. Jinxing company provides a full range of sputtering

coating targets (including metal targets, alloy and intermediate

alloy targets, ceramic targets) to colleges and universities,

scientific research institutions, industrial and mining

enterprises.

Magnetron sputtering target material forming method: the material

forming method is selected according to the product performance and

different requirements of customers. In general, when the melting

point of materials is low, it is necessary to use vacuum melting,

casting, forging and rolling to eliminate porosity. Of course,

effective heat treatment is necessary to refine the uniform grain

material. Materials with high melting point (or materials with high

brittleness) are formed by hot pressing or hot isostatic pressing,

and some are formed by cold isostatic pressing and then sintered.

All kinds of sputtering target materials provided by our company

have proper technology, high density, uniform grain and long

service life...

Titanium Aluminum alloy rod for Sputtering Target ,

Titanium Aluminum Alloy Sputtering Target are available in varying sizes

Vacuum sputtering targets and optical coating materials are widely

used in decorative coatings, tool coatings, optical coatings, and

coated glass and flat panel display industries. The produced

sputtering target has reasonable composition design, smooth and

smooth surface, and good electrical conductivity. The working

current is stable during sputtering, and the bottom plate of the

high-resistance target is firmly applied. , Good stability, good

heat resistance, wear resistance and oxidation resistance, small

temperature coefficient of resistance and other characteristics.

The target materials are prepared according to their material

characteristics: the hot-pressing sintering process and the vacuum

melting casting process. The products have the characteristics of

high purity, excellent microstructure and high utilization rate.

The target types are: flat rectangular, tube-shaped, disc-shaped,

ring-shaped, flake-shaped, powdery, etc. The specifications and

components can also be customized according to the specific

requirements of users.

| | Density(g/cm3) | Actual density(g/cm3) | Compactness density% | Ti50Al50at% 2N8 | 3.633 | 3.62 | >99% |

| | Density(g/cm3) | Actual density(g/cm3) | Compactness density% | Ti70Al30at% 2N6 | 3.99 | 3.987 | >99% |

Other compostion: 50:50at% 80:20at% 70:30at% 40:60at% 33:67at%

The main products are :

High purity aluminum Al, high purity copper Cu, high purity

titanium Ti, high purity silicon Si, high purity gold Au, high

purity silver AG, high purity indium in, high purity magnesium mg,

high purity zinc Zn, high purity platinum Pt, high purity germanium

Ge, high purity nickel Ni, High purity tantalum TA, gold germanium

alloy Auge, gold nickel alloy auni, nickel chromium alloy NiCr,

titanium aluminum alloy TiAl, copper indium gallium alloy cuinga,

copper indium gallium selenium alloy CuInGaSe, zinc aluminum alloy

ZnAl, aluminum silicon alloy AlSi and other metal coating

materials.

|