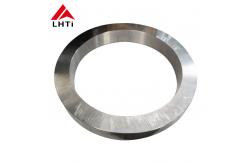

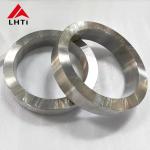

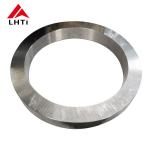

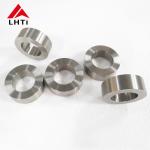

40 - 400mm Thickness Seamless Rolled Titanium Ring Gr5 Titanium Forged Ring

|

|

Seamless Rolled Titanium Ring Titanium Forged Ring Titanium Forgings

Low density and high strength.

Seamless Rolled Titanium Ring also referred to as seamless forged rings are starting blank products that go through additional forming, machining and grinding in order to produce finished components. In most cases, its production involves a process called ring rolling on rolling mills that vary in size. Through this process, parts can be manufactured to tight tolerances and specific geometries that come with outstanding surface smoothness and concentricity. Forged ring products can have an outside diameter of a few inches like the smallest washer-ring to much larger parts that are over 9 feet in diameter. The ring rolling process starts with a circular preform of metal that has been previously upset and pierced (using the open die forging process) to form a hollow “doughnut.” This doughnut is heated above the recrystallization temperature and placed over the idler or mandrel roll. This idler roll then moves under pressure toward a drive roll that continuously rotates to reduce the wall thickness, thereby increasing the diameters (I.D. and O.D.) of the resulting ring.

6. Related Products

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: 400mm Thickness Seamless Rolled Titanium Ring Seamless Rolled Titanium Ring Gr5 Titanium Forged Ring | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Chemical Industry Gr5 Titanium Ring Seamless Rolled Titanium Forgings |

|

40 - 400mm Thickness Seamless Rolled Titanium Ring Gr5 Titanium Forged Ring |

|

Gr11 Titanium Forged Ring Corrosion Resistant Chemical Industry Titanium Forgings |

|

Gr7 Titanium Forged Ring Polishing Chamfering Titanium Forgings |

|

200 - 1300mm Outer Diameter GR5 Titanium Ring Aerospace Titanium Forgings |

|

GR2 GR5 Titanium And Titanium Alloy Forged Ring Bright Surface |