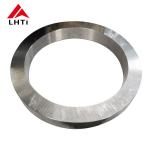

AMS4928 Bright Surface Forged Round Titanium Rings 6al4v Gr5

|

|

AMS4928 Forged Titanium Rings 6al4v Gr5

A titanium Seamless Rolled Ring is made in three steps. This process directs grain flow in tangential and radial directions and provides the pieces with the mechanical properties such as strength, ductility, and resistance to impact and fatigue. First: a preform is made on a press out of an ingot cut Second: a hole in punched on the center creating the form of a doughnut, Third: the preform is placed on a ring mill that expands the material to the right dimensions. Advantages of titanium Seamless Rolled Ring Forging For use in Oil & Gas, Power Generation, Mining, Aerospace and other critical applications, Performance-wise, there is no equal for Rolled Rings.

Product picture:

|

||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Titanium Seamless Rolled Ring AMS4928 Forged Titanium Rings Gr5 Forged Titanium Rings | ||||||||||||||||||||||||||||||||||||||||||||||||

|

Chemical Industry Gr5 Titanium Ring Seamless Rolled Titanium Forgings |

|

40 - 400mm Thickness Seamless Rolled Titanium Ring Gr5 Titanium Forged Ring |

|

Gr11 Titanium Forged Ring Corrosion Resistant Chemical Industry Titanium Forgings |

|

Gr7 Titanium Forged Ring Polishing Chamfering Titanium Forgings |

|

200 - 1300mm Outer Diameter GR5 Titanium Ring Aerospace Titanium Forgings |

|

GR2 GR5 Titanium And Titanium Alloy Forged Ring Bright Surface |