81 - 90 of 105

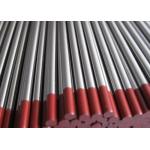

tungsten molybdenum arc

Selling leads|

...Tungsten Alloy Electrode for TIG Welding/Tungsten Electrode Surface conditions: grinding, cleaning, electrolyisis polishing, drawing or forging. ...

2024-12-09 22:00:03

|

|

...mark;polished molybdenum bar surface presents metallic luster and has no obvious oxidized phenomenon. The two surfaces have no defects, such as ...

2024-12-09 19:37:28

|

|

...mark;polished molybdenum bar surface presents metallic luster and has no obvious oxidized phenomenon. The two surfaces have no defects, such as ...

2024-12-09 22:00:03

|

|

.... Application : Used for insert gas protection arc welding, plasma cutting, spray-coating and furnace melting. Functions: Excellent welding ...

2024-12-09 19:37:28

|

|

... welding, plasma cutting, spray-coating and furnace melting. Functions: Excellent welding performance. Great arc starting capacity with good arc ...

2024-12-09 19:51:52

|

|

.... Application : Used for insert gas protection arc welding, plasma cutting, spray-coating and furnace melting. Functions: Excellent welding ...

2024-12-09 22:00:03

|

|

... welding, plasma cutting, spray-coating and furnace melting. Functions: Excellent welding performance. Great arc starting capacity with good arc ...

2024-12-09 22:00:03

|

|

..., sintering and infiltrating with copper. They are highly resistant to heat, electric arc, wear and deformation at high temperature welding, flash ...

2024-12-09 19:37:28

|

|

... Hardness W75Cu25 Tungsten Copper Alloy Bar Machined Parts With Corrosion Resistance Characteristics of WCu Alloy Tungsten copper alloy (generally ...

2024-12-09 21:05:58

|

|

..., sintering and infiltrating with copper. They are highly resistant to heat, electric arc, wear and deformation at high temperature welding, flash ...

2025-07-31 00:14:53

|