Customized High Temperature Resistant Rotary Kiln Idler Roller Gear Ring Accessories

|

|

Customized High-Temperature Resistant Rotary Kiln Idler Roller Gear Ring Accessories

Product Introduction

Product Advantages

Material Selection

Product Parameter

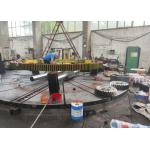

Product Display

Q&A Q: Why we believe in luoyang zhongtai industries co., ltd:

|

||||||||||||||||||||

| Product Tags: Customized Rotary Kiln Accessories High Temp Rotary Kiln Accessories |

|

Customized High Quality Cast Steel Ball Mill Pinion Gear Parts |

|

Customized 42CrMo Alloy Steel Hardened Gear Pinion Ball Mill |

|

Rotary Kiln And Ball Mill Gears High Load Bearing Capacity Stable Operation |

|

Large Casting Ball Mill Gear Ring Wear Resistant Stainless Steel |

|

Wear-Resistant Low-Noise Rotary Kiln Large Gear Ring Large Industrial Accessory |

|

Customized High Temperature Resistant Rotary Kiln Idler Roller Gear Ring Accessories |