OEM Casting And Forging Mill Girth Gear Steel Spur Large Diameter

|

|

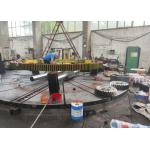

OEM Casting And Forging Mill Girth Gear Steel Spur Large Diameter Ring Gear

1. Manufacturing process of big tooth ring for mill girth gear (1) Blank The steel casting blank is provided by the heavy casting and forging Plant of CITIC Heavy Industry Machinery Co., LTD. It is implemented in accordance with gb11352-89 standard. Molding, smelting, pouring, box beating, cleaning and dressing castings according to casting process requirements; During the inspection and acceptance, the cast steel blank shall be checked according to the drawings and technical requirements, and the process shall be put down after passing the acceptance according to JB/T6402-92 standard. (2) Rough machining Draw lines according to the requirements of the drawings and set aside processing allowance, alignment, connection, processing inner and outer circle, milling joint surface, drilling and other processes. (3) Agent injury Ultrasonic inspection shall be carried out on the whole, and the internal quality shall meet the secondary requirements of GB7233-87 standard. (4) Normalizing pretreatment The half ring is normalized and tempered in pairs to provide good microstructure for subsequent surface quenching. And according to the requirements of the drawings to check the deformation of half gear ring after heat treatment. (5) Machining The first two half ring with high strength bolt connection into a whole ring, according to the requirements of the drawings processing of the whole ring circle and upper and lower end, and then according to the drawings and machining requirements for milling teeth. (6) Eliminate machining stress The integral ring is annealed to eliminate stress. (7) Surface quenching of integral gear ring Tooth surface medium frequency induction quenching along the tooth groove, hardness HRC50~55, effective hardening layer depth 3~5mm. (8) Final inspection Firstly, test whether the hardness of each groove of the gear ring after intermediate frequency quenching and tempering meets the requirements of the drawing; Secondly, detect whether the size of the maximum outer diameter D6944 is too large, such as the deformation of 3mm, need mechanical correction until qualified; Thirdly, for magnetic particle inspection of gear teeth and transition fillet, the quality should meet the secondary requirements stipulated in GB/T9444-88 standard; Finally, according to the drawings and technical requirements for the final inspection.

2. Product parameters of big ring for mill girth gear

3. Case introduction of large ring gear (1) The largest ring gear in China -- the largest ring gear in the world is coming off the assembly line in Luoyang Zhongxin Heavy Machinery Group Co., LTD., Henan Province. The ring has a diameter of 9.936 meters, an inner diameter of 7.950 meters, and a total weight of 80 tons. The outer end of the ring is lined with 274 teeth 0.9 meters high.

(2) Citic Heavy Machinery Co., Ltd. has signed a production contract with Wuhan Iron and Steel Group to manufacture the world's largest oxidized pellet sintering kiln for it. As a key part of sintering kiln, the processing of large ring gear attracts attention. Previously, Citic heavy machinery processing ring maximum diameter of 8.8 meters. The successful production of large gear ring of Wuhan Iron and Steel Co., Ltd. has achieved another significant breakthrough in the history of Chinese and world gear ring processing. The ring has a diameter of 9.936 meters, an inner diameter of 7.950 meters, and a total weight of 80 tons. The outer end of the ring is lined with 274 teeth 0.9 meters high. The successful production of large tooth ring has achieved another significant breakthrough in the history of Chinese and world tooth ring processing.

|

||||

| Product Tags: Mill Girth Gear Casting Mill Girth Gear Forging Large Dia Mill Girth Gear |

|

Customized High Quality Cast Steel Ball Mill Pinion Gear Parts |

|

Customized 42CrMo Alloy Steel Hardened Gear Pinion Ball Mill |

|

Rotary Kiln And Ball Mill Gears High Load Bearing Capacity Stable Operation |

|

Large Casting Ball Mill Gear Ring Wear Resistant Stainless Steel |

|

Wear-Resistant Low-Noise Rotary Kiln Large Gear Ring Large Industrial Accessory |

|

Customized High Temperature Resistant Rotary Kiln Idler Roller Gear Ring Accessories |