GS42CrMo4 Alloy Cast Steel Customize Mill Pinion Gears For Ball Mill

|

|

GS42CrMo4 Alloy Cast Steel Customize Mill Girth Gear For Ball Mill

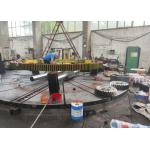

1. Introduction of mill girth gear customize ball mill gear ring Luo Mine specializes in the production of CITIC Heavy Industry ball mill ring gear, Luo mine produced ball mill half gear specifically includes: mineral processing ball mill ring gear, cement ball mill ring gear, semi-self-grinding machine ring gear, raw material ball mill ring gear. And can be customized to other brands of ball mill gear ring. GS42CrMo4 Alloy Cast Steel Gear

2. Introduction of big gear and small gear of mill girth gear The gear is made of ZG35CrMo alloy cast steel with heat treatment hardness OF HB260 ~ 300. Pinion material is 17CrNiMo6, carburizing and hardening + grinding process, tooth surface hardness HRC57 ~ 61. (1) Pinion gear A. Vacuum arc smelting, ladle refining, vacuum degassing materials; B. Forging in accordance with international standards, ultrasonic inspection forgings; (2) Big gear A. Casting adopts full ring riser technology; B. Use the simulation program to determine the appropriate curing process, determine the appropriate size of the gate, slope and riser, improve casting quality, reduce defects and reduce costs; C. Precision gear processing equipment, improve the accuracy and gear surface roughness; D. Finite element analysis of structural stress and deflection deflection of large gear, so as to determine the shape modification of pinion; E. When the big gear is processed on the machine tool, check the meshing of the pinion after finishing to ensure that the tooth shape and tooth direction of the two are completely consistent. GS42CrMo4 Alloy Cast Steel Gear

3. Processing technology measures of mill girth gear customize ball mill gear ring and pinion

GS42CrMo4 Alloy Cast Steel Gear GS42CrMo4 Alloy Cast Steel Gear FQA Q: Quality warranty? A: Guarantee time: one year for main machinery. If something wrong we will provide the technical advice and find solution immediately. For those wearing parts we guarantee high quality parts for long-term supply.

Q: After sales service? A: We can supply technical guide for machines running test and parts maintenance if end user needs.

After-sales service LUOYANG ZHONGTAI INDUSTRIES able to provide: 1. ENGINEERED SPARES - DESIGN AND MANUFACTURING 2. LARGE VOLUME STEEL AND IRON CASTING FOUNDARIES 3. HUGE MACHINE SHOP CAPABILITIES 4. TRAINING PROGRAMMES 5. PREVENTATIVE MAINTENANCE PROGRAMS 6. PREVETATIVE MAINTENANCE SERVICES 7. COMPREHENSIVE MAINTENANCE PROGRAMS |

||||||||

| Product Tags: Customize Mill Pinion Gears GS42CrMo4 Mill Pinion Gears GS42CrMo4 ball mill girth gear |

|

Customized High Quality Cast Steel Ball Mill Pinion Gear Parts |

|

Customized 42CrMo Alloy Steel Hardened Gear Pinion Ball Mill |

|

Rotary Kiln And Ball Mill Gears High Load Bearing Capacity Stable Operation |

|

Large Casting Ball Mill Gear Ring Wear Resistant Stainless Steel |

|

Wear-Resistant Low-Noise Rotary Kiln Large Gear Ring Large Industrial Accessory |

|

Customized High Temperature Resistant Rotary Kiln Idler Roller Gear Ring Accessories |