Rotary Kiln And Mining Mill Girth Gear Maximum Diameter 16m Factory Price

|

|

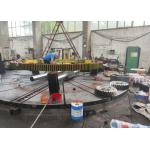

Mining Mill Girth Gear, Pinion Gear, Big Ring Gear With Maximum Diameter 16m

1. Girth Gears: Rotary kiln Girth Gear,ball mill Girth Gear Girth Gears offered find extensive application in different industry sectors including in sponge iron plants, steel & cement industry, mining industry, wind mills as well as in other industry sectors. These are made available in module range of 10 Module to 70 Module and in minimum diameters of 100 mm to 15000 mm. Further, these comprise maximum weight of 70 MT single pieces. Here the range of hardened & ground gear boxes/gears comprise Worm gear boxes, Helical / Double helical gears/gearboxes, Helical-Bevel gearboxes, Planetary Gearboxes and others.

2. Product parameters of big ring for mill girth gear

3. We provide girth gears in three different designs Fabricated steel Cast steel Ductile (Nodular) cast iron Fabricated gears became more common in the past and are constructed with forged steel gear rim materials and electro welded body structure. The rings are manufactured from a whole block of high resistance alloy steel. After the rough machining of the ring, we carry out hardening and tempering heat treatment in order to improve the mechanical characteristic and therefore its relevant performance.

External teeth Maximum diameter: 16000 mm

Internal teeth

Forging material process

|

||||||||

| Product Tags: Mining Mill Girth Gear Diameter 16m Mill Girth Gear Diameter 16m Kiln Girth Gear |

|

Customized High Quality Cast Steel Ball Mill Pinion Gear Parts |

|

Customized 42CrMo Alloy Steel Hardened Gear Pinion Ball Mill |

|

Rotary Kiln And Ball Mill Gears High Load Bearing Capacity Stable Operation |

|

Large Casting Ball Mill Gear Ring Wear Resistant Stainless Steel |

|

Wear-Resistant Low-Noise Rotary Kiln Large Gear Ring Large Industrial Accessory |

|

Customized High Temperature Resistant Rotary Kiln Idler Roller Gear Ring Accessories |