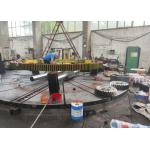

Custom 10-45mm Module Large Girth Gear pinion Ring For Grinding Mill

|

|

Custom 10-45mm Module Large Girth Gear pinion Ring For Grinding Mill

1. Type:1,1.25,1.5,2,2.5,3,4,5,6,8,10,12,16,20,25,32,40,50. 2. Standard: DIN; GB, GOST, AISI, etc. 3. Certification: ISO9001, Form E, Form A, CO 4.Report: Material Report; Hardness Report; UT/MT Report; Dimensions checking report; Mechanical Property Test Report girth gear material 42CRMO STEEL DATA CHEMICAL LIST C : 0.38-0.45% Si: 0.17-0.37% Mn: 0.50-0.80% S : Allow residual content <0.035% P : Allow residual content <0.035% Cr: 0.90-1.20% Ni: Allow residual content <0.030% Cu: Allow residual content <0.030% Mo: 0.15-0.25% MECHANICAL DATA Tensile Strength σb (MPa): >1080(110) Yield point σs (MPa): >930(95) Elongation σ5 (%): >12 Reduction of area ψ (%): >45 Akv (J): Impact absorbing energy Akv(J): >63 Impact toughness value αkv (J/cm2): >78(8) Hardness: <217HB Sample size: The blank size of the sample is 25mm PHYSICAL DATA Critical point temperature (approximate value): Ac1=730℃, Ac3=800℃, Ms=310℃ Linear expansion coefficient: temperature: 20~100℃/20~200℃/20~300℃ /20 ~400℃/20~500℃ /20~600℃ linear expansivity: 11.1x10K/12.1x10K/12.9x10K/13.5x10K/13.9x10K14.1x10K Modulus of elasticity: temperature 20℃/300℃/400℃/500℃/600℃, Elastic modulus 210000MPa/185000MPa/ 175000MPa/165000MPa/15500oMPa The Technical Data Sheet Of straight tooth gear ring

company show FAQ

Q: Why we believe in luoyang zhongtai industries co., ltd: A: 1. More than 30 years experience. 2.We are the leading professional supplier of mining machinery, construction machinery, machines casting and forged parts 3. All products achieved ISO9901:2000 quality management certificate and CE, ROHS certificates.

Q:Delivery time A: parts lead time 1-2months, machines 2-3months.

Q:Payment terms A: Accept payment type: T/T, L/C, Western union,Cash. 30% deposit when signed contract. Full payment paid before shipping

Q: Quality warranty? A: guarantee time: one year for main machinery. If something wrong we will provide the technical advice and find solution immediately. For those wearing parts we guarantee high quality parts for long-term supply.

Q: After sales service? A: we can supply technical guide for machines running test and parts maintenance if end user needs.

Aftersales service

ZTIC's Field Service Engineers are trained specifically in the

CITIC brand group products but are capable of undertaking the

servicing of other OEM brands. |

||||||

| Product Tags: 45mm Module Girth Gear Pinion 10mm Module Girth Gear Pinion 45mm Module rack pinion mechanism |

|

Customized High Quality Cast Steel Ball Mill Pinion Gear Parts |

|

Customized 42CrMo Alloy Steel Hardened Gear Pinion Ball Mill |

|

Rotary Kiln And Ball Mill Gears High Load Bearing Capacity Stable Operation |

|

Large Casting Ball Mill Gear Ring Wear Resistant Stainless Steel |

|

Wear-Resistant Low-Noise Rotary Kiln Large Gear Ring Large Industrial Accessory |

|

Customized High Temperature Resistant Rotary Kiln Idler Roller Gear Ring Accessories |