Helical Gear GS42CrMo4 Alloy Steel Ball Mill Ring Gear And Spur Gear

|

|

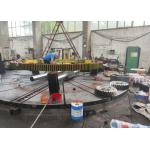

Product Description Ring Gears: Rotary kiln Ring Gear,ball mill Ring Gear

Girth Gears offered find extensive application in different industry sectors

including in sponge iron plants, steel & cement industry,

mining industry, wind mills as well as in other industry sectors.

These are made available in module range of 10 Module to 70 Module

and in minimum diameters of 100 mm to 15000 mm. Further, these

comprise maximum weight of 70 MT single pieces. Here the range of

hardened & ground gear boxes/gears comprise Worm gear boxes,

Helical / Double helical gears/gearboxes, Helical-Bevel gearboxes,

Planetary Gearboxes and others. Ø16m CNC Hobbing Machine Ø12m Gear Cutting Machine (Switzerland) Ø10m Hobbing Machine (Germany) Ø4m CNC High Speed Hobbing Machine (Germany) Ø1.6m Horizontal CHC Hobbing Machine (Germany) Ø5m CNC Profile Gear Grinding Machine (Germany) Ø2.8m CNC Profile Gear Grinding Machine (Germany) Ø1.25m CNC Profile Gear Grinding Machine (Germany) Ø1m CNC Profile Gear Grinding Machine (Germany) Ø0.8m CNC Profile Gear Grinding Machine (Germany) Automatic positioner

Our Services Aftersales service LUOYANG ZHONGTAI INDUSTRIES able to provide: 1. ENGINEERED SPARES - DESIGN AND MANUFACTURING 2. LARGE VOLUME STEEL AND IRON CASTING FOUNDARIES 3. HUGE MACHINE SHOP CAPABILITIES 4. TRAINING PROGRAMMES 5. PREVENTATIVE MAINTENANCE PROGRAMS 6. PREVETATIVE MAINTENANCE SERVICES 7. COMPREHENSIVE MAINTENANCE PROGRAMS LUOYANG ZHONGTAI INDUSTRIES’s Field Service Engineers are trained specifically in the LUOYANG ZHONGTAI INDUSTRIES brand group products but are capable of undertaking the servicing of other OEM brands. Our technicians are equipped with the most advanced technological diagnostic equipment available to trouble shoot your equipment to optimise performance and minimise down time. LUOYANG ZHONGTAI INDUSTRIES also has an extensive capability in supplying all you consumable and electrical/ mechanical spare part needs. FAQ Q: Why we believe in luoyang zhongtai industries co., ltd: A: 1. More than 30 years experience. 2.We are the leading professional supplier of mining machinery, construction machinery, machines casting and forged parts. 3. All products achieved ISO9901:2000 quality management certificate and CE, ROHS certificates.

Q:Delivery time: A: Parts lead time 1-2months, machines 2-3months.

Q:Payment terms: A: Accept payment type: T/T, L/C, Western union,Cash. 30% deposit when signed contract. Full payment paid before shipping.

Q: Quality warranty? A: Guarantee time: one year for main machinery. If something wrong we will provide the technical advice and find solution immediately. For those wearing parts we guarantee high quality parts for long-term supply.

Q: After sales service? A: We can supply technical guide for machines running test and parts maintenance if end user needs. |

||||||||||||||||||||||||||||||||||||

| Product Tags: 70 MT Mill Ring Gear HB 250 Mill Girth Gear 70 MT Ball Mill Ring | ||||||||||||||||||||||||||||||||||||

|

Customized High Temperature Resistant Rotary Kiln Idler Roller Gear Ring Accessories |

|

Customized High Quality Cast Steel Ball Mill Pinion Gear Parts |

|

Customized 42CrMo Alloy Steel Hardened Gear Pinion Ball Mill |

|

Rotary Kiln And Ball Mill Gears High Load Bearing Capacity Stable Operation |

|

Large Casting Ball Mill Gear Ring Wear Resistant Stainless Steel |

|

Wear-Resistant Low-Noise Rotary Kiln Large Gear Ring Large Industrial Accessory |