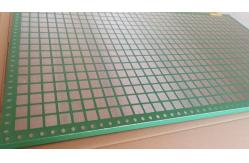

Mining Vibrating SS Fluid Solid Control Mud Screen

|

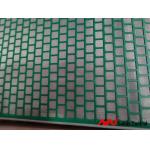

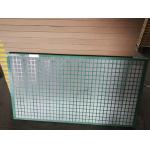

FLUID SYSTEMS®™ shale shaker screens conformed stainless steel replacement API 13C manufacturerfloMAX D™ series screens replacementThe floMAX D™ series screens are de-blinding screen panels that utilize a perforated support plate for added mesh support and reparability. The series of screens are manufactured using ultra-fine cloth square mesh and are available in mesh sizes from 20 to 400. As with all Fluid Systems, Inc. replacement screen frame panels, each screen is factory tensioned to eliminate improper tensioning in the field. flowMAX RTM screens replacementThe flowMAX RTM screens consist of two layers of durable rectangle opening wire cloth above a heavy support cloth. The de-blinding characteristics of the three-layer mesh configuration allows for better flow rate efficiency. The lightweight frame allows for less screen flexing and more g-force transfer between screen and shaker basket. The diamond-shaped openings in the screen frame prevent liquid channelling by distributing the flow evenly across the screen surface. The FMR series screen is manufactured using the powder coating adhesive process. Fluid System Screen Panels specifications

Briefs of Aipu shaker screenOur screen panels are available for most shale shakers. All screens are manufactured with high-quality stainless steel wire mesh, and all wire cloth checked for conformance to tolerances and visually inspected for weaving flaws. Advanced manufacturing processes and a stringent quality assurance program ensures that only the highest quality screens are shipped. All screens and a wide range of screen meshes are API RP 13C Shaker screen life varies because of shaker conditions, mud condition, drilling condition, and the operator, etc. That means if the screens were from one batch and holding the same mesh size but life lasts different there might be the above reasons. For example, we drill an oil well in Kuwait use the OBM the extra thin screen cloth will help to get better penetration or conductance and leadless mud block or mud overflow but the life may be shorter since the fragile wire. When we use screens holding the same API size and the same configuration at some Yan'an oilfield sites use WBM, the screen life will be much longer. Since the general viscosity and mud condition is better than in Kuwait. Some users find even everything is the same, the screen life performs differently. Please do check again, the shaker's condition, such as the tensioning system, the bed seal, the spring condition, etc.. Besides, the shaker operator professionality is important. Some workers can handle screens professionally and easily, but some of them even don't know to clean and put screens in the right places after every shut-off. The mud engineers will test drilling fluids time by time. This will tell us how to do further process. They don't check active mud property but also check the disposed of mud. They will evaluate whole mud volume and general mudflow situation. The capable mud engineers give the optimal suggestion on mud use and screen use. Finally, we'll get the optimal solution on solids control for whole good drilling and save necessary cost What screens do AIPU Solids produce?We make screen panels for our Hunter series shaker. Including MG, D, and Miniseries. Furthermore, we provide replacement shaker screens for a famous model, such as 500, 2000, Mongoose, MD, KC, and so on. And the screen panels including the flat pattern, corrugated pattern. The frames can be metal framed or composite frame. The Installation way including the hook strap and the wedge blocked one. Besides the existing model and brands, we are also willing to provide the ODM and OEM screen panels for clients. Tell us your shaker design, the screen panels you may prefer. Combine your demand and our professional suggestion then you'll get the optimal solution on shaker screen. Even the solution to your shaker and system. Aipu shaker screens are of high quality and API RP13C conformed. Screens tested by the professional lab. The API sized screen will provide convenience to select proper screens. As we know the API designation of the screen is a range of cut points under the D100 standard. Every range means the possible high-performance at different drilling section and condition Please feel free to contact AIPU for more information on shaker screen panels. No matter you need price, or a picture or any question. Just come to us for all solutions of shaker screen The below sheet is for your reference to confirm the possible demand. They are API size normally used

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Fluid Solid Control Mud Screen SS Solid Control Mud Screen | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

304L Steel Shale Shaker Screen Solids Control Green Colour |

|

Mining Vibrating SS Fluid Solid Control Mud Screen |

|

API 13C Wearing Parts Drilling Mud Shale Shaker Screen |

|

Shale Shaker Screen Replacement |

|

Drilling Mud Solids Control Equipment Shale Shaker Screen With API Standard |

|

API Hook Strip Flat Shale Shaker Screen 100 Mesh 1053 X 697mm |