ECOOGRAPHIX T-800Q CTP Thermal Plate Making Machine

|

|

New Era Of Top End T-800Q Thermal Computer To Plate CTP

--- ❀ --- ❀ --- ❀ --- ❀ --- Brief --- ❀ --- ❀ --- ❀ --- ❀ ---

ECOOGRAPHIX T-800 Q (F, V, X) A New Era of Top End CTP ---Super fast, Supreme Imaging Quality, Full Automation(Inline punch built in)

--- ❀ --- ❀ --- ❀ --- ❀ --- Specification --- ❀ --- ❀ --- ❀ --- ❀ ---

T-800Q (F, V, X)S

F V X

External Drum

825nm laser

Throughput 35plates/hour, 45plates/hour, 55plates/hour

Max. 1163mm x 940mm

0.15mm, 0.30mm

Standard: dual resolutions 2400dpi and 1200dpi or optional 2540dpi and 1270dpi. Variable high resolution option: maximum up to 10000dpi at fast scan direction

0.01mm

Optical Fiber

Plate Loading Standard: Simplified Autoloader or multi-cassette Autoloader(four cassettes)

Optional: Internal punching(maximum four sets of plate holes)

CTP: 1200kg, Simplified Autoloader: 200KG, Multi-cassette

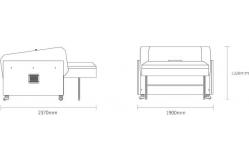

Autoloader: 570KG Machine Size(WxLxH)mm 1900 x 2370 x 1320

CTP(Single phase: 220V; Max. power(Peak Value): 4KW) Simplified Autoloader(Single phase: 220V; Max. power(Peak Value): 900W) Multi-cassette Autoloader(Single phase: 220V; Max. power(Peak Value): 1100W) Operation Environment Recommended: 21-25℃, Allowable Temperature: 15-30℃, Relative Humidity: 40-70%

--- ❀ --- ❀ --- ❀ --- ❀ --- Details --- ❀ --- ❀ --- ❀ --- ❀ ---

New Laser Head Technology makes the plate making performance stable. At the same time, the speed is improved by leaps and bounds.

Linear Motor In addition to high acceleration, linear motor drive also has extremely stable operation and high positioning. Accuracy, providing the guarantee for high precision and accurate printing.

Motor Direct Drive Drum The application of direct motor driving drum technology makes our star-up time accelerated and greatly improves productions efficiency.

Full-automatically Continuous Printing With Inline Punch Equipped with automatic plate loading and unloading, automatic feeding and automatic punching function, it can work continuously without interruption to maximize the performance.

Automatic Plate Feeding Cassette Large capacity automatic plate feeding system can load 400 plates at the same time and support four specifications of automatic plate switching, which saves manpower and improves printing speed for you, easily achieving full-automatically continuous plate printing.

Digital Square Spot Imaging Digital square screen ensure the integrity of the image and the sharp feature of the picture quality. The transmission from digital information to paper greatly reduces the image loss and significantly increase the printing resistance.

--- ❀ --- ❀ --- ❀ --- ❀ --- Producing And Packaging --- ❀ --- ❀ --- ❀ --- ❀ ---

From producing to delivery, we make every details very carefully to guarantee the good product quality and service to customers.

--- ❀ --- ❀ --- ❀ --- ❀ --- Certificates --- ❀ --- ❀ --- ❀ --- ❀ ---

--- ❀ --- ❀ --- ❀ --- ❀ --- FAQ --- ❀ --- ❀ --- ❀ --- ❀ ---

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: CTP Thermal Plate Making Machine 825nm laser Plate Making Machine 35plates/hour ctp printing machine | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

FP-1400 Perfect CTP Plate Machine For Large Format Flexo Plate Processing |

|

FP 800 Drying And De Tacking Flexo CTP Plate Processor |

|

Drying and De-tacking Flexo CTP Plate Processor |

|

FP-900 Solvent Based Flexo CTP Plate Processor |

|

FP-900 920mm*680mm Solvent Based Flexo CTP Plate Processor |

|

Multi Functional Solvent Based Flexo CTP Plate Processor All In One |