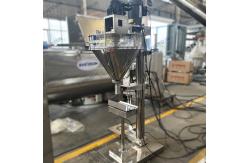

Fully Automatic Flour Wheat Powder Packaging Machine Vertical Powder Quantitative Filling Machine

|

|

This powder quantitative packaging scale is made of stainless steel, which is corrosion-resistant, sturdy, and durable, with a long service life. The machine uses a screw feeding device based on the characteristics of powders that are not easily fluid. There is an arch-breaking device in the material bin, which loos the material before screw conveying, making the material less likely to form arches. The packaging machine uses an electrically actuated weighing mechanism, with adjustable air cylinder and outlet pressures, ensuring more reliable and pure operation. Main components and their functions Pneumatic Clamping Device and Bracket: Mounted on the load cell, it is used for rapid and slow filling of materials. Weigh System: A high-speed response weighing system is adopted to ensure packaging accuracy. Servo Motor: Drives the lifting of the tray, the lifting speed can be arbitrarily, and there is almost no dust during filling, reducing environmental pollution. PLC Control and Human-Machine Interface: PLC control is adopted, and the touch operation is simple, making it easy for users to get started quickly.

Workflow 1. Manual bagging or canning: The preparation work begins. 2. Container elevation: Elevate the container to an appropriate position. 3. Rapid filling: Start rapid filling of the material. 4. Container descent: The container gradually descends during the filling process. 5. Weight reaches pre-set: When the weight reaches the pre-set value, enter the slow filling stage. 6. Weight reaches target value: Once the final weight reaches the set target value the filling is completed. 7. Manual removal of the container: Finally, the packaged container is manually removed.

1. Dust and explosion-proof design: Specially designed dust removal device effectively reduces dust pollution in the working environment.

2. High-precision system: Advanced weighing technology ensures packaging accuracy.

3. Flexible working modes: Supports both fixed quantity and real-time weighing modes to meet different needs.

4. Easy operate and maintain: Equipped with a touch screen interface, simple and intuitive operation, convenient maintenance.

5. PLC control and touch screen interface display make operation simple.

Powder automatic packaging machines are widely used in various industries, excelling in scenarios where efficient and precise packaging of powdered materials is required. For instance, in industries such as chemical, food, and pharmaceuticals, there are strict requirements for packaging powdered raw materials, and powder automatic packaging machines can meet these needs, enhancing production efficiency and product quality.

Company ProfileWe have been specializing in the production of Screening and conveying equipment for 13 years. China's vibrating screen industry top three. And we have done matching and OEM for many large companies. Including the world's top vibrating screen manufacturer, Sweco, USA, we have OEM for his China region. And our products are often exported to Australia, Thailand, Indonesia, New Zealand and other countries.

|

||||||||||||||||||||

| Product Tags: Quantitative filling powder packaging machine Vertical powder packaging machine Fully automatic powder packaging machine |

|

Fully Automatic Flour Wheat Powder Packaging Machine Vertical Powder Quantitative Filling Machine |

|

Fully Automatic Flour Wheat Powder Packaging Machine Vertical Powder Quantitative Filling Machine |

|

Custom Stainless Steel Powder Particle Packaging Machine Five Grains And Cereals Automatic Quantitative Packaging Machine |

|

Automatic Milk Powder Packaging Machine Automatic Weighing Powder Packaging Machine |

|

10-50kg Automatic Weighing Packaging Machine For Powder And Granular Materials |

|

Solid Powder Quantitative Packaging Scale Explosion-proof Automatic Packaging Machine |