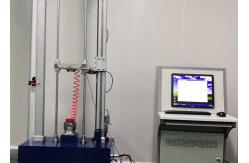

IEC 62133-1 Battery Acceleration Impact Test System With Vibration Damping

|

|

IEC 62133-1 Battery Acceleration Impact Test System With Vibration Damping

Product information:

It conforms to IEC62133-1:2017 clause 7.3.4, IEC62133-2:2017 clause 7.3.8.2, IEC 60225-1 clause 6.13.2, IEC 60225-27 clause 10.6.2.2 and clause 10.6.2.3, IEC6IEC60086-4 clause 6.4.4, IEC 60068-2-29, IEC 60335-2-25 Annex BB, YD/T 2344.1 and etc.

Technical Parameters:

Measuring Control System Main Technical Parameters:

Shock Impact Test System Main Technical Parameters:

Application:

This fully automatic shock test system is designed for measuring and ensure shock performance of products and packages. It can do normal shock test with half sine wave, square wave, sawtooth wave etc., simulate products under real environment shock conditions, thus improve the products and packages structure.

Feature:

1. This automatic shock test system with Windows operating system, easy for operation, operator only need to type into testing data, system will automatic configurate parameters and control machine, finish shock test accurately. 2. With anti-re-shock brake device, shock table fall freely, when shock wave pad rebound, hydraulic brake piston impact thus shock table braking, avoid secondary shock and achieve accurate shock data. 3. With effective vibration damping device; for large shock tester, when do shock testing it has large instantaneous impact force, this device largely reduced the shock impact to the floor, small than 350×350mm ones no need special foundation, easy for installation. 4. Digital setting of shock height, shock table automatically lifting, with high control accuracy and good repetitively. 5. Configured with shock measuring system, shock energy data and wave with real time display. 6. With high acceleration generator, for small testing specimens which need high acceleration shock test, able to fix high acceleration generator on shock table, it can obtain higher acceleration than IS series shock tester according to impact energy transfer principle. For specimen smaller than 200×200mm the testing requirements is: peak acceleration 5000-50000m/s2, acceleration duration time 0.2~1ms.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Battery Acceleration Impact Test System IEC62133-1 Battery Acceleration Impact Test System | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

High-Safety Battery Heavy Impact Test Machine Impact Weight 9.1KG UN38.3 |

|

UL 2054 Battery Heavy Impact Test Machine 9.1±0.1KG Impact Weight 1000mm Height |

|

Hydraulic Vertical Shock Test System With Half-Sine Waveform Generator |

|

EN 50604-1 Mechanical Shock Test System Impact Tests Of Half Sine Wave For Battery Cells |

|

EN 50604-1 Battery Vibration Test System for Cell Pack Impact & Reliability Testing |

|

Battery Mechanical Shock Test System Half-Sine Sawtooth Square Wave Shock Tests |