Xenon Accelerated Aging Environmental Chamber Air - Cooled PLC Control

|

|

Air-cooled Xenon Accelerated Aging Environmental Chamber for Weathering Resistance Test

Overview:

This Xenon est chamber uses a xenon lamp to simulate the effect of sunlight, condensation moisture is used to simulate rain and dew, and the material to be tested is placed in a cycle of alternating light and moisture at a certain temperature. The test can be performed in days or weeks. Reproduce the hazards that occur outdoors for months or even years. Artificial accelerated aging test data can help select new materials, transform existing materials, and evaluate how changes in formulations affect product durability.

It conforms to follwoing standards: ISO 4892-3:2006 “Plastics-Methods of exposure to laboratory light sources-Part 3: Fluorescent UV lamps” IEC60068-2-5 “Environmental testing -Part 2-5: Tests-Test Sa: Simulated solar radiation at ground level and guidance for solar radiation testing, IDT” GBT2423.24-2013 “Environmental Testing-Part 2: Test Methods-Test Sa: Simulated solar radiation at ground level and guidance for solar radiation testing” ASTMG155,ISO10SB02/B04,SAEJ2527,SAEJ2412

Structure and configuration:

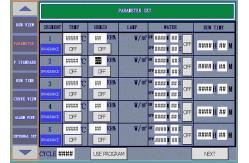

1. Enclosure material:SUS304 Stainless steel dusting; 2. Inner chamber material:SUS304 Stainless steel plate; 3. Door: Silicone rubber tight sealing device; 4. Sample frame:Stainless steel,Sample fixing position adjustable, standard stamping forming template; 5. Controller: PLC &Touch Screen,programmable; 6. Convection: Long axis special motor; 7. Equipment operation timing controller; 8. Black panel thermometer BPT; 9. Special filter (sun filter); 10. Irradiance meter: Intelligent automatic irradiation intensity compensation, automatic correction of irradiance.

Technical Parameters:

(The above branded components are for reference, the final may vary

according to different requirements)

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: environmental simulation chambers ess test chamber | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

IEC 60950 Heating Cabinet for Electronics Safety Testing 225L Temperature RT+10°C ~300°C |

|

Explosion-proof Walk-In High and Low Temperature Humidity Test Chamber 8.36m³ |

|

IEC 60068-2-78 Walk-in Temperature and Humidity Test Chamber 3.38m³ Temp. -40~+100℃ |

|

ISO 4892-1/2 Water-Cooled Xenon Weathering Test Chamber Irradiance Range 0.3W/M2~1.1 W/M2 |

|

IEC 60068-2-11 1M3 Compound Salt Corrosion Test Chamber Spray Pressure 70~170Kpa |

|

80L Air-Cooled Thermal Shock Test Chamber -40°C To +150°C Test Range |