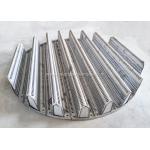

Duplex 2205 Anti Corrosion Tower Internals Liquid Distributor 1.Liquid distributors Liquid distributors is installed upper of the random packing. It is

important to get even distribution of water or other liquid.Liquid distributors have many types such as trough type,pan

type,deck type,channel type and pipe type. 2. Choice of liquid distributor: Column Diametermm | Specific liquid loadM3/m2*h | System fouling tendency | Turndown ratio | Suitable type of liquid distributor | 250 - 900 | 0.75 - 5 | Low - medium | <10:1 | Trough type liquid distributor with sumpDeck type liquid distributor with orifices on drip tubes | 5 - 30 | Low - medium | 2:1 | Pan type liquid distributorTrough type liquid distributor with sump | >30 | Low - medium | 2:1 | Pan type liquid distributorTrough type liquid distributor with sumpDeck type liquid distributor | >900 | 0.75 - 5 | Low - medium | <10:1 | Trough type liquid distributor with parting boxDeck type liquid distributor with orifices on drip tubes | 5 - 30 | Low - medium | 2:1 | Trough type liquid distributor with sumpTrough type liquid distributor with parting boxDeck type liquid distributor | >30 | Low - medium | 2:1 | Deck type liquid distributorTrough type liquid distributor with sump |

3. How to choose liquid distributor? Liquid distributor is the most important column internal from a

process point of view. It is required to distribute liquid

uniformly at the top of packing tower. Meanwhile a liquid

distributor must have sufficient gas passage area to avoid high

pressure drop or liquid entrainment.Characteristics of an ideal liquid distributor:Uniform liquid distribution; Resistance to fouling; Proper trundown

capabitity;Low gas pressure drop; Minimum height; Higher

cross-mixing capabity.When we need to select a liquid distributor, we need to consider

the tower diameter, flow rate, turndown ratio, available height (in

case of revamp) and fouling resistance.Weir type gravity distributor:Generally speaking, the weir type gravity distributor is one of the

least troublesome distributors. It has excellent trundown

capability and can handle large liquid load. However it can usually

provide only a limited number of drip points (minimum 30 number of

weirs per m2). It is also extremely sensitive to levelness and

liquid surface agitation. 4. Applications of Liquid Distributor 1. Distillation towers,2. Scrubbing towers,3. Steam drum,4. Evaporators,5. Knockout drum,6. Sulfuric acid plants,7. Petrochemical plants,8. Flue gas desulfurization,9. Refineries,10. LNG plants, 5. Trough liquid distributor production

Welcome your contact with your private tower internals plan or

ideas! |