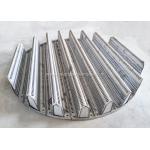

316l Plate 900mm Air Jet Distillation Tower Trays With Liquid Downcomer

|

|

316L plate 900mm air jet tower tray with liquid downcomer

1. Hualai factory air jet tower tray,

This is an efficient tray developed on the basis of new vertical sieve tray. It has good adaptability to the conditions of large diameter tower and high gas-liquid load. Radial phase guide jet tray has the characteristics of high flux, high efficiency, low pressure, high operation flexibility, anti blocking and long operation cycle.

2. Various types of tower trays,

3. Where is radial phase guide jet tray from?

Vertical sieve plate Several large holes (100 ~ 200 mm in diameter) are arranged on the tray. On the holes, a bubble cap with many sieve holes on the side wall is set. There is a gap at the bottom of the bubble cap for liquid to enter into the cap.

The two-phase upward flow is formed by drawing the liquid into the hood from the bottom gap of the hood into a liquid film, and the two-phase separation occurs after the two-phase flow is ejected through the sieve holes on the side wall of the hood, that is, the gas rises and the liquid falls back to the tray. The liquid flow from the tray inlet to the downcomer will experience the above process many times. Compared with the ordinary sieve plate, the vertical sieve plate provides a large and constantly updated interphase contact surface for gas-liquid two-phase, which strengthens the mass transfer process; The initial velocity of droplets in the vertical direction is zero, which reduces the entrainment of liquid foam. Therefore, the vertical sieve plate can obtain higher tray efficiency and larger production capacity.

4. Hualai factory of tower trays and tower packing,

Our main business runs around columns / towers, which are widely

used in oil refinery, petrol-chemical industry, chemical industry,

pharmacy, fertilizer industry, etc. With the customers’ requirement

for full series of tower internal products, we are working with

famous universities in related area, and developing our capacity in

tower internal designing, manufacturing and service. We can now

design, produce and supply liquid distributor, liquid collector and

re-distributor, structured packing support, random packing support,

bed limiter, chimney trays, etc.

5. The main requirements of industrial production on tower trays are as follows:

Among these requirements, the high efficiency should be considered for the separation operation requiring high purity of the product; For the general separation with large treatment capacity (such as crude oil distillation, etc.), the main consideration is large capacity of passing.

6. Hualai workshop for tower internals

Welcome your contact with your private tower internals plan or ideas! |

||||||||||||||||||||||||

| Product Tags: 900mm distillation tower trays air jet distillation tower trays distillation tower trays with liquid downcomer |

|

Column Diameter 400mm Tower Internals Random Packing Plate Hump Support |

|

Metal Customized Column Ss304 Tower Internals Random Packing Plate Hump Support |

|

Diamerter 500mm Distillation Tower Internals Random Packing Support Plate Ss304 |

|

Ss304 Packing Support Random Grid Plate Type Hump |

|

Diameter 1000mm Random Packing Support Plate Tower Internal |

|

Ss316 Gravity Type Distillation Column Internals Tower Liquid Distributor |