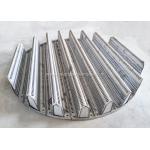

Packed Tower Internals Air Inlet Uniform Distributor 316l Material

|

|

Packed tower internal air inlet uniform distributor 316L material

1. Hualai factory packed tower internal air inlet uniform distributor,

Packed tower is a mass transfer equipment of gas-liquid two-phase, and its mass transfer efficiency is determined by whether the gas-liquid two-phase can be fully contacted, and one of the keys to the full contact of gas-liquid two-phase is the uniform distribution of gas.

2. Hualai factory Tower internal Products,

3. The specific requirements for the air inlet distributor.

Among these requirements, good uniformity and low resistance are the main ones.

4. Relationship between gas distribution and packed bed

The initial gas distribution should be considered in the low pressure drop packed bed. Horner takes the pressure drop less than 8.3 mm H2O / m as the boundary; The initial gas distribution should be considered in the packed column with shallow bed. Many scholars regard the bed height with height diameter ratio less than 0.5-1 as the boundary line to distinguish the shallow bed; Even if the height diameter ratio of the packing layer is greater than 1, the initial gas distribution is also very important; The main reason is the uneven distribution of gas flow into the packed bed. Therefore, the study of gas distribution in packed tower is mainly to study the pre distribution of gas and the design method of inlet structure to achieve uniform pre distribution.

5. Packed column classification - view of gas distribution requirements

According to the requirements of uniform distribution of gas flowing into packed bed, the packed tower can be divided into four types (1) Large diameter shallow bed packed tower; (2) Medium and small diameter shallow bed packed tower; (3) Large diameter packed tower; (4) Medium and small diameter packed tower. In the above classification, the bed with height diameter ratio less than or equal to 1 is shallow bed, and tower diameter greater than 2 m is large diameter. (1) Due to the worst distribution ability of the packed bed itself, the gas distributor is the most ideal way to realize the uniform distribution of the air flow in the bed almost completely by the pre distribution of the inlet structure. (2) Due to the low bed height, the uneven initial distribution can not be transformed into uniform distribution in the bed. Therefore, the uniform pre distribution of gas flow into the bed is also required to improve the mass transfer efficiency. As the diameter of this kind of tower is small, it is not difficult to make the inlet air evenly pre distributed as long as the inlet pipe structure is designed reasonably or the measures such as adding uniform grid are adopted. For the other two types of tower, especially (4), due to the large height diameter ratio of the bed, it has better uniform distribution performance, so the distribution requirements can be lower. However, special attention should be paid to the influence of inlet pipe structure, packing support plate and bed structure on the uniform distribution performance.

6. Hualai workshop for tower internals

Welcome your contact with your private tower internals plan or ideas! |

||||||||||||||||||||||||

| Product Tags: packed tower internals 316l material tower internals air inlet uniform distributor tower internals |

|

Column Diameter 400mm Tower Internals Random Packing Plate Hump Support |

|

Metal Customized Column Ss304 Tower Internals Random Packing Plate Hump Support |

|

Diamerter 500mm Distillation Tower Internals Random Packing Support Plate Ss304 |

|

Ss304 Packing Support Random Grid Plate Type Hump |

|

Diameter 1000mm Random Packing Support Plate Tower Internal |

|

Ss316 Gravity Type Distillation Column Internals Tower Liquid Distributor |