Aluminum Alloy Low Pressure Metal Casting Tools With Die Casting Process

|

|

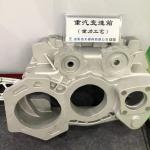

Aluminum Alloy Low Pressure Casting Mould of Front Frame for Automobile

Established in 2001, Luoyang Liushi Mould Co., Ltd. is the national standard-setting unit for mold-forming molds of lost foam casting. The company now has 6 invention patents and 20 utility model patents. Its main business is concentrated in three major fields: lost foam molds, metal casting molds and aluminum alloy castings.

What is die-casting?

Die casting is a manufacturing process for producing accurately dimensioned, sharply defined, smooth or textured-surface metal parts. It is accomplished by forcing molten metal under high pressure into mould cavity. Most die castings are made from aluminium, zinc, and magnesium alloys. Depending on the type of metal being cast, a hot or cold chamber machine is used.

We are equipped with excellent precision CNC machining centers.

Services include automatic washing, Chromating/chemical conversion coating, e-coating, electro-static power painting, and wet painting.

Trimming, Shot-blasting, Polishing, Vibrating, Tumbling, Hand-filing, Drilling and Tapping, Aging/Tempering.

Aluminum Alloy Low Pressure Casting Mould Description

Aluminum Alloy Low Pressure Casting Mould Proudct Range

Transportation, Agricultural machinery equipment, Construction machinery, Water conservancy facilities, Space flight and aviation, Chemical machinery, Sea carriage and so on.

Manufacture Process

Pressure Casting Mould Features

Our Advantages

Company profile

Luoyang Liushi mould Co., Ltd was established on 2001, which is

National Standard Setting Unit for Lost Foam Casting Mould. The

company is located in the Millennium Emperor, peony flower city of

Luoyang City. We have 9800 office building, and 22000 workshop,

which is well equipped with research, development, design, foundry,

machining, assembly, surface treatment and other equipment. It′s a

Luoyang municipal R&D center and technology center. Company technicians can provide on-site guide mould assembly, test production, free repair and complete technology for lost foam casting proecss according to customer demands. With the business philosophy of "careful design, lean manufacture, best service, perfect quality", we strive to provide satisfactory products and services for customers. After years of development, our company has become the preferred mould suppliers of many lost foam casting manufacturers and the exclusive supplier.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: gdc die casting gravity mold casting | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Low Pressure GDC Aluminium Gravity Die Casting Sinotruk Gearbox |

|

Foundry A356 A319 Aluminium Gravity Die Casting Parts As Drawing |

|

A413 ZL101 Aluminum Gravity Die Casting Auto Parts Sand Casting |

|

OEM ODM Aluminium Gravity Die Casting Tempering Annealing Heat Treatment |

|

Tolerance 0.01-0.05mm Aluminum Die Casting Alloys For Automobile Medical |

|

High Precision ADC12 ADC10 Aluminium Gravity Die Casting Machinery Parts |