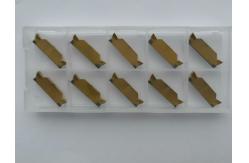

Perfect Surface CNC Grooving Insert / Face Grooving Inserts OEM /

ODM AvailableMGGN 300Low noise, Low vibration, High Efficiency Machining Cermet Inserts are excellent for all machining applications where

specifications for high surface quality, dimensional stability and

tight tolerances must be adhered to. They guarantee long tool life

with small to medium chip cross sections and uniform allowances,

and are ideal for fine finishing, finishing and rough finishing of

steel, sintered metal and ductile cast iron.It has a reinforced

structure that provides excellent chipping resistance, reducing the

wear on the insert and preventing sudden fracture. 1. Description Type: Grooving insert Material: Cermet Model Number: MGGN300 Origin: China Application: Grooving Advantage: Perfect surface Grades: MC1020 ISO grade: P10, P20 Coating: Coating or uncoating Lead time: With one week normally Term of payment : T/T 2. Advantages of Cermet - High quality surface on the workpiece for finishing and

semi-finishing. Turning/milling instead of grinding can be

realized;

- High oxidation resistance--high red hardness and high cutting

speed in dry cutting (Environmentally friendly);

- Hign chemical stability--No Built- up edge (No chemical

interaction between workpiece and cutting edge);

- Low density--Low cost, lightweight operation; low cutting force--

low noise machining;

- Natural resources advantage--Less W &Co (Strategic reserve

resources) needed. In the long run, raw materials are easier to

obtain.

3. Advanced preparation technology of the whole industrial chain 4. Grade Introduction Cermet Grade Introduction | Grade | Density (g/cm3) | Hardness (HRA) | Transverse Rupture Strength (MPa) | Fracture Toughness (MPa*m1/2) | Workpiece | Applications | Features | MC102A | 7.1 | 92.8 | 2000 | 8.5 | Aluminium Alloy, Nonferrous Alloy, Carbon Steel | Finishing, Semi-finishing, grooving | Low cutting force, high anti-adhensive, high quality roughness | MC102B | 7.1 | 93.2 | 1800 | 8.0 | Bearing Steel | ID/OD grooving, RD chamfer, sealing groove, in bearing industry | High red-hardness and wear resistance for dry cutting | MC1020 | 6.8 | 92.5 | 2200 | 9.0 | Carbon steel with hardness under 28HRC, Alloyed Steel | Finishing, Semi-finishing | Exordinary wear resistance in continous finishing machining.

Provides stable finishing to machine steel, as well as gray cast

iron and sintered alloy. It's a high wear resistance and high cost

performance uncoated materials | MC2010 | 6.8 | 92.8 | 2100 | 9.0 | Carbon steel with hardness under 35HRC, Alloyed Steel | Finishing, Semi-finishing | Anti-collapse and wear resistance performance strengthened

materials is utilized which can provide extra reliable roughness

for extensive cutting conditions | MC1120 | 6.8 | 92.5 | 2200 | 9.0 | Carbon steel with hardness under 28HRC, Alloyed Steel | Finishing, Semi-finishing | Exordinary wear resistance in continous finishing machining with

TiC/Ti(CN) coating, provides stable finishing to machine steel, as

well as gray cast iron and sintered alloy. It's a high wear

resistance and high cost performance uncoated materials | MC2210 | 6.8 | 92.8 | 2100 | 9.0 | Carbon steel with hardness under 36HRC, Alloyed Steel | Finishing, Semi-finishing | High lubricant performance PVD coating is used in this grade to

realize the high class machining. It is a coated cermet with both

high wear resistance to ensure high class surface machining in

univeral applications |

5. Why Choose Us - The sole one in China focus on cermet products only and

cermet grinding solution,

- Manufacturer of integrating row materials, R &D, design,

manufactureing.

- Over 30 years focus on cermet materials research and development.

- The best R &D team of cermet in China.

- The sole one in China own all the technologies of every process.

- Equipped with the best machines, like press machine from

Osterwalder, Grinder from Agathon.

- Our grade is equivalent to TN60, NX2525, CT3000, T1200A, CN2000,

NS530, etc.

- ODM service is provided.

|