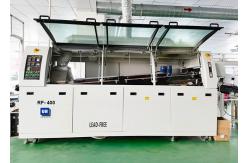

PLC Control 300mm PCB SMT Soldering Tin Machine Lead Free Design

|

|

PLC Control 300mm PCB SMT Soldering Tin Machine Lead Free Design

Features : 1. Totally lead free design. 2. Japan made Mitsubishi PLC Control 3. Synchronous insert plate structure Japan made conveyor power equipped steady transportation. 4. Shaped stream line design, flexible operation, convenient to be cleaned and maintained. 5. Preheated by high efficient stainless steel heating pipe, good heat compensation and high stability. 6. Low oxidation anti-erosion alloyed tin furnace, energy saving design of spraying nozzle fulfill lead free request absolutely. 7. External casting heating board of tin furnace with high efficiency. 8. Acoustic and optical warning and emergency brake system.

Specification :

The Function of Wave Soldering Machine Wave soldering refers to the melting of solder (lead-tin alloy) through an electric pump or an electromagnetic pump sprayed into the solder wave crest required by the design, so that the printed board with pre-installed components can pass through the solder wave to achieve component soldering Soldering of mechanical and electrical connections between terminals or pins and printed board pads.

|

||||||||||||||||||||||||||||||||||||||||

| Product Tags: 300mm SMT Reflow Soldering Machine Lead Free SMT Soldering Tin Machine 300mm SMT Soldering Tin Machine | ||||||||||||||||||||||||||||||||||||||||

|

Solder Pot AC220V 410kg Wave Soldering Machine 750mm Conveyor RF-350A |

|

8.5KW SMT Reflow Soldering Machine |

|

10 Zones SMT Reflow Soldering Machine |

|

BGA CSP Components Reflow Oven Equipment 7 Zones SMT Reflow Oven RF-H700 I |

|

410kg Solder Pot Wave Soldering Machine 750mm Conveyor Height RF-350A |

|

PLC Control 300mm PCB SMT Soldering Tin Machine Lead Free Design |