VCTA-D810 Flexible Automated Optical Inspection Equipment Double Conveyor Online AOI

|

VCTA-D810(Double Conveyor On-Line AOI)Intelligent double conveyor structure design, double conveyor programs can be free to switch. Two sets of inspection system can share the database, can output the SPC report.

Machine Features

Flexible/Multi-function AOI It can be placed at several quality controlling points in SMT Line to check 2D paste printing quality, inspect component defects before reflow soldering, inspect PCBA quality after reflip soldering and DIP wave soldering Smart Double Conveyor AOI The same series multi-configuration apply for different requests Double conveyor design The first conveyor is fixed, the second and the third conveyors are automatically adjustable, the fourth conveyor can adjust manually,The maximum width of the 1-4 Conveyor is 686mm. The inspection range between:50×50mm~450×300mm. Database sharing and statistical functions All internal AOI are managed via central server, all single machines are in remote control. SPC reports will be generated through collection and analysis of all data to promote process improvement and improve products passing rate

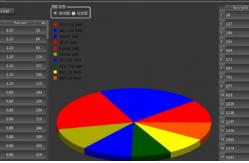

Detailed SPC Analysis ReportTo generate a variety of visual reports through analysis and statistics from testing results of all products.

Machine Specifications

Our factory |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: 1kw automated optical inspection equipment Flexible automated optical inspection equipment Double Conveyor Automatic Optical Inspection Machine |

|

VCTA-D810 Flexible Automated Optical Inspection Equipment Double Conveyor Online AOI |

|

Online AOI Automatic Optical Inspection Machine High Resolution Camera For 0201 Chip |

|

VCTA-S810L Automatic Optical Inspection Machine Online AOI For PCB Optical Inspection |

|

VCTA-S820L Automatic Optical Inspection Machine Online 2D AOI For SMT Line |

|

VCTA-S810E Online AOI Automated Optical Inspection Vector analysis algorithm For PCB |

|

A410 Desktop Multi Function AOI Automated Optical Inspection Machine Color CCD Camera |